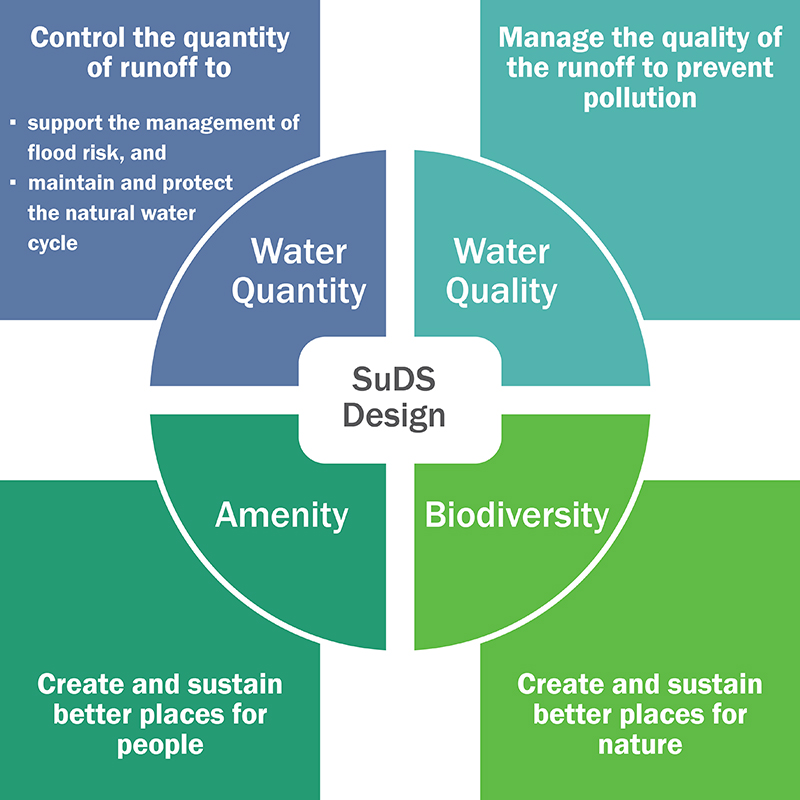

Water Quality Management – mitigating the impact of pollutants in surface water runoff to prevent harmful discharges into the environment – is one of the fundamental principles of SuDS Best Practice. Essentially, this covers three key material groups:

Increasingly, Water Quality Management is a key focus for SuDS systems. Planners are looking to provide “nutrient neutrality” i.e., reducing existing sources of nutrient pollution to mitigate the nutrients generated by new development. In these more demanding cases, removal of additional substances such as compounds of phosphorous and nitrogen are often required.

It is the job of key stakeholders in the Project Team to ensure that the water quality discharge meets the requirements of legislation, client, and the local environmental regulator.

Numerous reference sources exist that can help users determine the most appropriate water quality mitigation measures for a specific project. These include the CIRIA publication C753 The SuDS Manual. Chapter 4 deals with Designing for Water Quality and Chapter 26 deals with Water Quality Management. Chapter 14 relates to Proprietary Treatment Systems. Other Chapters provide guidance on specific vegetative “soft” SuDS components such as Detention basins, Swales, Infiltration systems and Filter strips. Vegetative SuDS are generally regarded as preferable in terms of SuDS Best Practice, as they are surface based solutions that manage rainfall closest to where it lands, also referred to as “source management”. Like any system, vegetative SuDS will require maintenance to ensure that they meet their design function throughout the lifetime of a development.

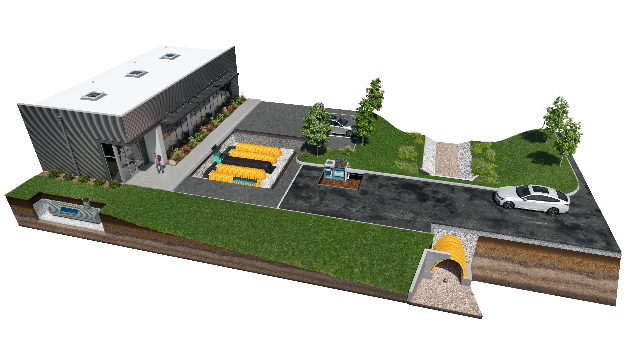

Designing an effective below ground SuDS attenuation system that meets the demands of both flood risk mitigation (Water Quantity Management) and pollution risk mitigation (Water Quality Management) requires a Management Train approach, where proprietary Water Quality Treatment device(s) are usually installed upstream of the below ground Attenuation Tank. This would typically require a sediment capture system, which may be as basic (and potentially inadequate?) as a catch pit or more appropriately, a proprietary gravity separation sediment tank or hydrodynamic separator. Hydrocarbon removal will require a bypass or full-retention oil/water separator, depending on the intended use of the development and the level of risk of hydrocarbon pollution.

Below ground attenuation systems such as crates and pipes offer little in the way of water quality treatment capability, so the demands of water quality must be covered by separate, additional SuDS components elsewhere in the system.

Not only can this require significant capital investment in the treatment system (each manufactured treatment device can cost >£10k, and multiple units may be required on a project), there is an additional operational cost in terms of inspection and maintenance. Failure to properly maintain water quality treatment systems can lead to problems with the attenuation tank, such as sedimentation within the tank, resulting in reduced storage volume– causing the system to fail hydraulically – and the possibility that pollutants are flushed downstream, resulting in water quality breaches and fines.

Some systems, however, include an integrated solution. New to the UK, the ADS StormTech stormwater attenuation system incorporates the unique Isolator Row, a patented, built-in water quality treatment device designed to remove silt and other polluting material flushed off the surface during rainfall.

Isolator Row has 2 treatment stages, contributing to the overall efficiency of the system. These include initial gravity separation of the silt and particulates within the Isolator Row chamber and filtration through a layer of woven geotextile fabric on the bed of the chamber, laid over a stone foundation. Two further treatment stages can take place within the stone embedment surrounding the StormTech chambers. As flow passes through the system, pollutants can adsorb onto the face of the stone, meaning that they are “trapped” and prevented from passing through to the discharge point. This material can provide nutrient for bacteria and over time, will be broken down into harmless, non-polluting material.

The four treatment stages of a StormTech system:

Isolator Row has been independently tested by universities and respected industry bodies (including NJCAT) and validated to remove over 80% of Total Suspended Solids (TSS) plus metals, hydrocarbons, phosphorus, nitrogen, and other surface water pollutants.

Where nutrient neutrality is sought and there is a demand for higher levels of pollutant removal, or where more challenging pollutants need to be dealt with, other water treatment solutions may be required. These can include proprietary filtration systems designed specifically to address certain chemical species and material phases within the surface water runoff. In these situations, when considering a proprietary manufactured treatment device, it is recommended that advice is sought directly from the manufacturer.

For practitioners in the UK, it may be helpful to refer to the British Water Code of Practice: Assessment Of Manufactured Treatment Devices Designed To Treat Surface Water Runoff. This publication sets out an assessment method to measure pollutant capture and retention. Additionally, read in conjunction with the Code of Practice and the CIRIA SuDS Manual, it is possible to derive mitigation indices using the British Water How To Guide: Applying The CIRIA SuDS Manual (C753) Simple Index Approach To Proprietary/Manufactured Stormwater Treatment Devices.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine June 2022