Monthly Archives: March 2022

Converting stormwater into a sustainable water supply

The Francisco Street Reservoir now serves as a source of useful non-potable water at a park for the local community, thanks to a stormwater collection system underneath.

Francisco Street reservoir was the first large reservoir in San Francisco, California when originally built in 1859. Decommissioned in the 1950s, the site was to be redeveloped but the Francisco Park Conservancy fought to keep it as a natural resource that would include harvesting rainwater. Underneath the 1.8 hectares Francisco Park is a stormwater capture and reuse system which was installed in 2021 to perpetually provide water for the park’s irrigation and toilets.

How the stormwater system works

The stormwater is stored in a 1.9M litre cistern at the top of the hill before being transferred to the service building, where it flows through a series of filtration and disinfecting processes. This ensures that the water meets public health regulations, while saving 5.7M litres of potable water every year.

The engineers decided to use a system of arched chambers because they would provide the largest storage volume per square metre.

“The reservoir is on a slope that is just under 20%. It’s a very challenging site from a variety of perspectives,” explains Sherwood Design Engineers (San Francisco) principal Cody Anderson who is responsible for the stormwater system.

“Normally you’d have your catch basin at the bottom of the site. Here, the historic reservoir is midway up the slope, so half the runoff is collected via gravity flow and the rest collected at the bottom of the site and pumped. All captured runoff flows through the screening filtration and into the chambers for storage and later use.”

Equipment used

Three hundred and seventy two ADS StormTech chambers, were installed using a 35m by 45m area of the existing reservoir and then covered with soil. This gave a total storage capacity of 2,000m3 of water in a 1,682m2 footprint. ADS StormTech chambers provided the best ratio of storage volume to footprint area.

The StormTech chambers are independently tested, BBA-approved and fully compliant with ASTM F2787, F2418 and F2922 stormwater storage systems standards. StormTech is typically used for below ground SuDS attenuation projects and more than 2.5M chambers have been used successfully around the world in over 40,000 projects. Three StormTech Isolator Rows are included in the Francisco Street reservoir system. These patented water quality treatment devices are integral to the StormTech system. They capture the “first flush” and trap sediment and other pollutants coming from stormwater runoff.

StormTech chambers come in a wide range of sizes, making them easy to install for all conditions. They are highly adaptable and can be configured around obstacles as well as affording multiple inlet and outlet positions. Standard pipe manifolds, manhole and access chamber inlet/outlet structures and flow controls can be used.

Reclaiming an area of San Francisco

“There are competing products on the market,” says Anderson. “We needed to store as much water as possible in the given area. We work on projects around the globe with an emphasis on sustainable development and we’re known for having the vision and the technical capacity.

“The Francisco Park is one of those projects of a lifetime. It’s reclaiming an area in the city of San Francisco that is now a beautiful park for the people.”

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.

SuDS tips #2: Efficient SuDS Systems depend on Effective Design

A qualified civil engineer, Stuart Crisp has been at the forefront of construction and a specialist in drainage systems for over 35 years. He has contributed to the development of numerous British and International Standards and industry specifications, and was a member of the project steering group for CIRIA C753 The SuDS Manual. In this regular series of articles, Stuart considers the different challenges facing designers and installers of below ground SuDS attenuation systems. This month covers speed and efficiency of construction.

Everyone knows that time is money. However, there’s rarely been such pressure on build time.

Sites are starting late. COVID 19 and Brexit has created labour shortages and manufacturers are struggling to meet demand. And with Britain now officially 6% wetter than in the previous 30 years, weather-related delays are only going to increase – particularly at this time of year. It’s no surprise that across the industry, site programmes are impacted, and contractors are struggling to meet deadlines and avoid penalty clauses.

Considering the speed of installation of the SuDS system at the design stage, can make life significantly easier for clients and contractors alike.

With large diameter pipes, site logistics, transport movements and storage space need to be factored in. Pipes are not the most efficient in terms of the amount of attenuated storage that can be achieved per delivery, and the footprint area required for a given attenuated storage volume is usually greater than most other forms of proprietary solution.

Vaulted systems can be slow to construct, and whilst geocellular crates are often quicker to install, difficulties with maintenance and the need for reliable pre-treatment often count against them. New to the UK, ADS StormTech chambers are fast and easy to work with, often requiring no mechanical lifting. They also provide easy access for inspection and are simple and low cost to maintain.

An important consideration in a drainage system is managing the hydraulic requirement against the available footprint area and construction depth. Traditionally, the flexibility of geocellular crates has made them a popular choice for tight footprints. However, ADS StormTech chambers are available in a range of sizes; the larger size chambers can accommodate the required attenuation volume in asmaller footprint, and the smaller chamber sizes can enable shallow construction depths in situations with high groundwater levels, minimum cover depth below traffic loads and shallow outfalls.

More flexible systems, such as ADS StormTech, are even able to maintain the necessary hydraulic flow around obstacles such as lighting columns.

The difference is particularly noticeable when it comes to more difficult terrain, especially when obstacles, such as lighting columns, below ground utilities and other structures need to be accommodated. Whilst solutions such a permeable block paving remain viable, large diameter pipes, geocellular crates and vaults are often unable to easily maintain continuous hydraulic flow through the system. StormTech chambers, are highly adaptable and can be configured around obstacles and afford multiple inlet and outlet positions. Standard pipe manifolds, manhole & access chamber inlet/outlet structures and flow controls can be used.

Whilst it’s perfectly possible to accommodate such terrain within a more traditional system, it can add time and complexity at both the design and installation stages. More flexible solutions may exist to optimise the design, improve efficiency and performance.

It’s important that the designer takes all these factors into consideration and is fully aware of the product types available and the pros and cons of each. An informed decision can then be made, fully understanding how the choice of system will impact on installed cost, performance, efficiency, buildability and maintenance.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine April 2022

SuDS tips #1: Below ground water attenuation systems – engineering considerations

A qualified civil engineer, Stuart Crisp has been at the forefront of construction and a specialist in drainage systems for over 35 years. He has contributed to the development of numerous British and International Standards and industry specifications, and was a member of the project steering group for CIRIA C753 The SuDS Manual. In the first in a regular series of articles, Stuart considers the different challenges facing designers and installers of below ground SuDS attenuation systems. This month, it’s the primary engineering considerations.

Most new build sites across the UK will now have a requirement for a water attenuation system in order to control stormwater that lands on the site. Before sites are built on the ground it will often naturally soak up rainfall however when new buildings are created there is nowhere for the rainfall to go. Water attenuation systems work by holding back the water in a storage vessel on site and slowly releasing the rainwater to the storm drain at a rate in which the infrastructure can handle.

Whilst there are many different types of stormwater storage and attenuation solutions: permeable block paving, geocellular crates, large diameter pipes, vaults and plastic corrugated arch structures such as ADS StormTech, not all systems provide the same attributes. Product choice is therefore central to the engineering solution. A simple designation of inflow rate, outflow rate and storage volume could result in a poorly executed project.

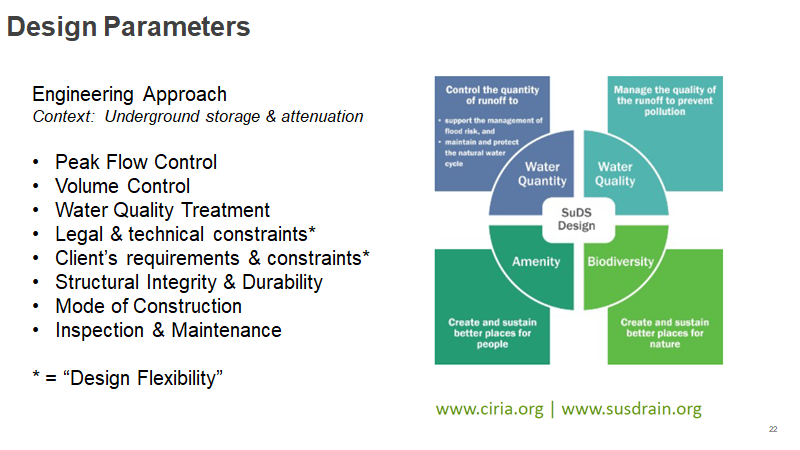

A well-designed attenuation project will not only consider the hydraulic functionality of the system (flow control and volume control), but also the fundamental principles of SuDS Best Practice, often cited as the four pillars of SuDS, i.e. Water Quantity, Water Quality, Biodiversity and Amenity.

Aligning the engineering design parameters for below ground attenuation with the four pillars of SuDS Best Practice

Consideration of these design parameters may lead to a decision to provide attenuation below ground. Cost of land is frequently the main consideration and the developer’s desire to maximise the return on their investment, although other issues such as Planning Gain and a requirement to provide parks, car parks or other civil amenities could also be a factor. In this context, it should be noted that all four pillars of SuDS Best Practice may not be achievable, although the hydraulic performance of the system is essential and must always be satisfied to mitigate against flooding.

To help achieve SuDS Best Practice, some proprietary below ground systems can provide integral water quality treatment, such as the StormTech system from Advanced Drainage Systems (ADS). This solution can contribute to the water quality requirements of the project without the need for additional expensive equipment. Other systems that are unable to provide water quality treatment may require additional SuDS components, such as separate pre-treatment for silt removal.

ADS StormTech includes Isolator Row – a ‘free’ water quality treatment device

At the design stage, a number of other limitations should be considered, such as legal and technical constraints and the client’s specific requirements. The below ground structure will become an infrastructure asset and as such it will require appropriate structural robustness and durability.

It is also vital to consider how the attenuation system will be built. The choice of system used can affect speed and cost of construction and other factors such as the number of transport movements to/from site, storage space, footprint to volume ratio, excavation and muck-away costs, minimum depth of cover, invert depth / construction depth / proximity to groundwater all need to be considered as part of the optimum design solution. Crucially – and often overlooked – is the ease of inspection and cost-effectiveness of maintenance. Sometimes, the most traditional solution in terms of hydraulic requirements, can give the client an ongoing problem in terms of effective cleaning and upkeep.

Over the coming months, we shall be taking a closer look at all of these factors and how best to accommodate them in an optimised SuDS attenuation system.

To find out more about ADS UK’s Water Attenuation Systems contact us today on 0203 442 0607 or click here.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine March 2022