Monthly Archives: November 2022

Doing SuDS attenuation differently

StormTech arch-shaped SuDS attenuation chambers from Advanced Drainage Systems have been used on over 50,000 projects worldwide. New Eurocode modelling demonstrates they pass muster for projects in the UK and Europe too.

With a global track record that stretches back decades, an underground SuDS attenuation system that exploits the structural properties of the arch is now being designed and installed on construction projects in the UK.

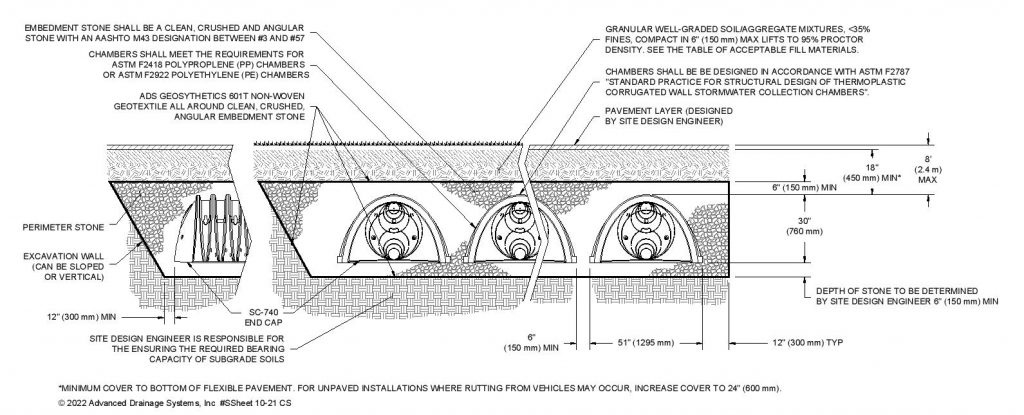

The heart of the StormTech system is its corrugated thermoplastic chambers which have an elliptical arch-shaped cross section. This elliptical profile shapes the embedment around the chambers into stone arches and structural columns, transferring loads away from the chamber into the stiffer material surrounding the chambers so that they can be installed at both shallow and deep cover. Designed for flexibility of layout, ease of installation and transportation, the StormTech system can also incorporate an integral means of removing surface runoff pollutants at no extra cost – which is easy to maintain and can remove the need for costly pre-treatment systems.

Produced by US drainage giant Advanced Drainage Systems (ADS), which is also the largest recycler of plastic in North America, StormTech chambers are designed to US codes and Standards, AASHTO and ASTM International. To ease their acceptance in the UK and other European countries, ADS commissioned a study to model their performance under the Eurocode design methodology.

ADS’s UK manager Stuart Crisp explains: “The US design philosophy is different to the Eurocode one,” he says. “This study translates the US approach and demonstrates with complete certainty that the StormTech system performs under the Eurocode design models, when installed using our standard construction details.”

Testing scenarios

To investigate the performance of the StormTech system, the seven different sizes of chambers were put through their paces using a finite element analysis (FEA) model, which looked at limit state modes of failure as set out EN 1991-2 – Eurocode 1 – Actions on Structures – Part 2. Some engineers may be familiar with CIRIA C737, which covers the design of thermoplastic crates for underground water attenuation, which also suggests Eurocode modelling as a means of demonstrating structural adequacy.

As per ISO/DIS 4982 which covers arch-shaped chambers, the FEA model was used to test the various chambers in the most demanding loading scenarios. At shallow depths, it is live traffic loads at the surface that are most likely to cause failure. For maximum cover, it is the long-term loading of the backfill material which must be considered.

Load models for four different stress and fatigue cases were applied, according to EN 1991-2 with cover in accordance with the ADS StormTech Construction Guide.

The modelling considers the shape of the arches and material properties. The sections are injection moulded from a thermoplastic, which means that the long-term performance of the material under loading must be taken into consideration.

Performance proven

The FEA modelling proved that all the StormTech chambers are structurally adequate for each of the load cases detailed above. For minimum cover situations, there is significant additional structural capacity; for maximum cover, more of the chambers’ capacity was used but they were still comfortably within their capacity.

Crisp hopes that these calculations will help engineers and contractors to make the case for using StormTech. “Contractors are already using the system because they see the benefits in cost-effectiveness, particularly when expensive pre-treatment systems can be eliminated and when excavation depth can be reduced for installations under roads with HGV traffic,” says Crisp. “This study means that when designers and installers want proof of structural performance to Eurocodes, evidence is to hand.”