Blog Archives

Water qualitatively and quantitively: managing storm water down a ‘treatment train’

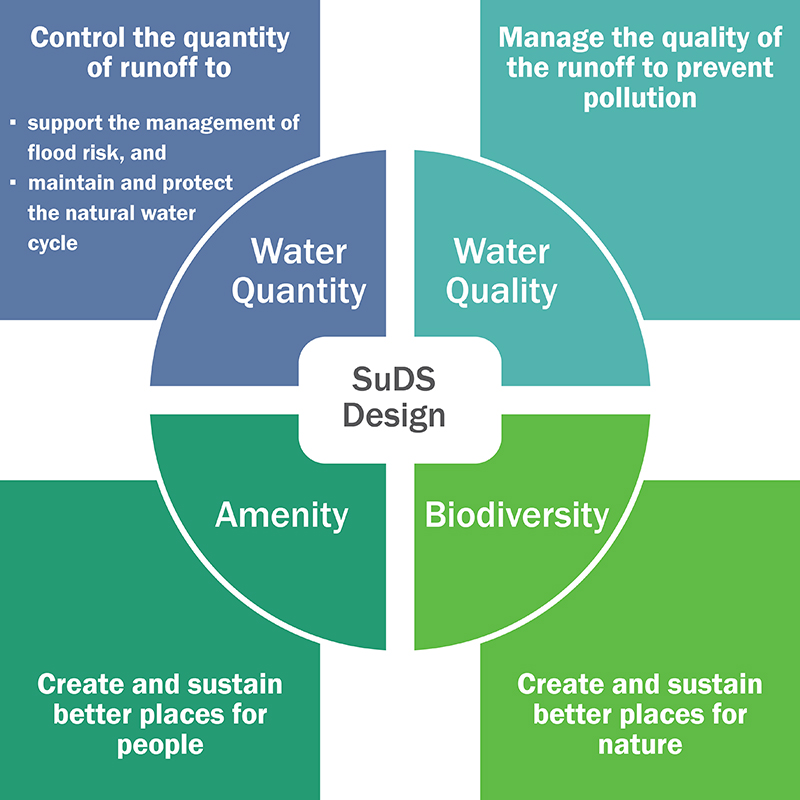

HISTORICALLY, driven by legislation, there’s a tendency to focus on water quantity – how to use SuDS to reduce or delay release of stormwater into sewers and prevent flooding. However, new legislation requires the additional focus on water quality. The SuDS treatment train considers water quality and prevention of pollution from stormwater runoff (alongside flood risk mitigation), with the level of treatment provided based on the anticipated levels and types of pollution.

A SuDS treatment (or management) train should start with prevention such as reducing impermeable surfaces, to reduce run-off and remove sources of pollution. Next comes source control, where rainfall is dealt with close to where it falls by infiltration-based elements such as soakaways, rain gardens and permeable pavements. Site control sees water managed within a local area, for instance directing water to a soakaway or infiltration device and then onto an attenuation pond or tank. Finally, regional control would see a system that could handle run-off from several sites, perhaps resulting in a detention basin or wetland.

The SuDS Manual, C753, published by CIRIA, prescribes a risk-based approach to designing SuDS for water quality. If pollution risks are deemed to be low, then SuDS designers can prioritise water quantity, amenity and biodiversity. If they are medium, then all considerations must be balanced. And if they are high, water quality evaluation must take precedence. It should however be noted that in all cases, including medium and low pollution risk sites, appropriate mitigation should be put in place to reduce the risk of pollution.

There is a range of water quality treatment measures that can be included in a SuDS train. Sometimes it is possible to use a completely natural SuDS train to deal with both water quantity and quality issues. At other times, the best solution combines natural and engineered SuDS elements, or may require proprietary manufactured elements only. This could be due to high levels of pollution loading or the space available.

There are four main types of pollutant that can be found in stormwater run-off: sediments, metals, hydrocarbons and nutrients. Sediments, often referred to in pollution mitigation as total suspended solids (TSS), is particulate matter. It includes tiny particles of soil, such as silt and clay, which have been dislodged by rainwater as it passes over the run-off surfaces.

Metals and metal compounds can be dissolved in run-off or attached to silts and sediments in the water. Copper and zinc are most commonly found in surface water in the UK but there can be cadmium and other toxic metals too. Although plants require very small amounts of copper and zinc to grow, higher concentrations can be damaging to them.

Hydrocarbon pollution comes with run-off from roads, car parks and areas where machines operate and are maintained, due to oil and fuel spills, tyre and brake wear. Changing climate means that rainfall events can be further apart but more intense, which can lead to higher concentrations of pollutants from roads, as they build up for longer before being washed away.

Nutrient pollution, usually nitrogen or phosphorous based, can come from sources such as run-off from agricultural land where fertiliser has been used or combined sewer overflows (CSOs), where sewage and surface water are mixed and discharged into bodies of water. They can lead to algal blooms, which reduces oxygen levels in the water and can negatively impact on aquatic habitats.

Capturing TSS pollution should generally be the focus of water treatment strategies in SuDS design since this removes both the solid particles and any pollution clinging to them. This can be done using a natural SuDS feature, such as planting for bioretention or a swale. Manufactured components such as filtration devices, silt traps or vortex separators can also be used upstream to remove solids before water is discharged into ponds, for instance.

Removal of sediment and solids is also important from a water quantity perspective. Build-ups reduce the capacity of a water storage element, whether natural or manufactured. How and when to remove sediment should be considered at the design stage and should be part of a planned maintenance regime.

Without a means of reducing suspended solids upstream of an attenuation device, sediment build-up within the device can reduce its efficiency over time. Some recently introduced underground arch-shaped SuDS attenuation devices have their own built-in systems for intercepting solids which are fast and simple to maintain.

Mitigation indices

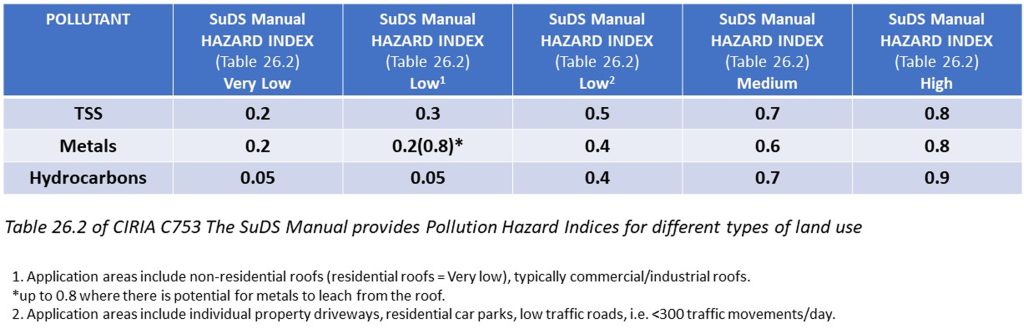

The SuDS Manual sets out a simple method for dealing with water pollution risks, requiring the determination of pollution hazard indices for the area under consideration and then matching a SuDS device with matching mitigation indices.

In Table 26.2, the manual provides pollution hazard indices for a range of applications and for three types of pollution: TSS, metals and hydrocarbons. So, for example, for a busy public car park such as a supermarket or hospital, the index for TSS is 0.7, for metals is 0.6 and for hydrocarbons 0.7.

The next step is to identify a form of SuDS treatment that can provide the necessary mitigation indices, either as a single treatment stage or using a combination of components. The Manual has a table for that too, Table 26.3. However, this table only provides mitigation indices for natural SuDS components. The mitigation indices for the natural SuDS components were compiled by a team of experts, drawing information from a selection of published papers.

Mitigation indices for proprietary manufactured treatment systems must be provided by the manufacturer using recognised test methods and 3rd party verified data.

British Water has published a Code of Practice for the Assessment of Manufactured Treatment Devices Without a means of reducing suspended solids upstream of an attenuation device, sediment build-up within the device can reduce its efficiency over time. Some recently introduced underground arch- shaped SuDS attenuation devices have their own built-in systems for intercepting solids which are fast and simple to maintain

Designed to Treat Surface Run-off. It uses rainfall time-series data for the UK to determine an appropriate treatment flow rates based on first-flush principles and uses a combination of two established test protocols – the German Deutsches Institut für Bautechnik (DIBt) and the New Jersey Corporation for Advanced Technology (NJCAT) from the US to create the British Water test methods.

In 2022 British Water published a ‘how to’ guide, Applying The CIRIA SuDS Manual (C753) Simple Index Approach To Proprietary/Manufactured Stormwater Treatment Devices, which provides a calculation methodology to derive mitigation indices for TSS, metals and hydrocarbons based on the British Water Code of Practice, or the DIBt or the NJCAT, test results. This enables manufacturers of proprietary treatment products to have their mitigation indices published so that they can be considered as part of a SuDS management train.

British Water publishes a List of Assessed Surface Water Treatment Devices, details of which can be found on their website.

For more information on Advanced Drainage Systems’ SuDS attenuation components, including a handy Design Tool, Mitigation Indices Data Sheet, Structural Design Technical Note and Installation App or to book a CPD, go to www.adspipe.co.uk

SuDS: Maintenance Matters

Designers need a better understanding of the maintenance requirements of different SuDS components to ensure that the systems they design will perform as intended. Stuart Crisp, UK manager at Advanced Drainage Systems (ADS), reports.

The issue of SuDS maintenance has always been a thorny one. Research suggests that the question of who will be responsible for the maintenance, and the cost of it, has been a prime factor in their slow uptake in the United Kingdom.

With the Government’s intention to implement Schedule 3 of the Flood and Water Management Act 2010 (FWMA) in England, making the installation and adoption of SuDS mandatory, concerns over maintenance issues again come to the fore. Developers, designers and installers need to understand the maintenance implications for alternative solutions considered for a project (in addition to, for example, hydraulic performance, structural integrity and water quality) and then offered to the adopting body responsible for the long-term operation of the SuDS asset. For underground attenuation devices, these vary significantly.

The more onerous the maintenance requirements, the higher the risk of them not being properly executed. The impacts of poor maintenance regimes and difficult-to-clean systems can be significant, increasing the risk of blockages – leading to loss of capacity and flooding – and pollutants washing out into water bodies.

Guidance

The SuDS Manual, CIRIA C753, recognizes that underground attenuation crates are ‘difficult to clean’ and that their capacity will reduce over time. Section 21.5.3 of the manual recommends that the size of crates should be increased by 10% to allow for accumulation of sediment. This applies even when a maintenance programme is deployed, since it isn’t always possible to remove all sediment during cleaning. Commercial developments, high density residential development, car parks and highways face the highest potential loss of storage, according to the guidance.

For both crates and large diameter pipes, some form of silt separation and removal system upstream is normally required to slow down the rate of sediment build-up and to remove some of the pollutants that cling to those particles. These upstream components must also be inspected and cleaned at intervals prescribed in a SuDS maintenance plan.

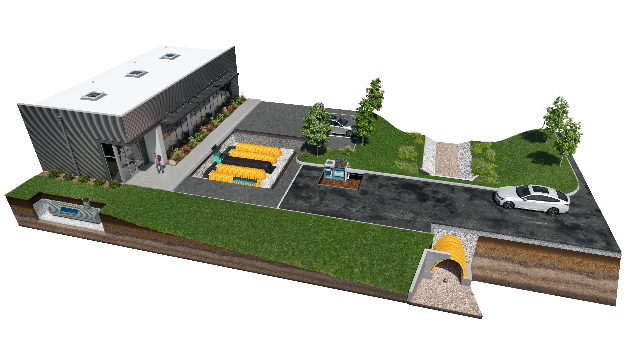

In designing its StormTech underground attenuation device, ADS sought to remove the need for costly upstream pre-treatment. An inbuilt ‘Isolator Row’ – essentially a modified version of the standard StormTech elliptical arches – collects the sediment before the water moves into the main body of the system.

Independent tests have demonstrated that the Isolator Row removes over 80% of total suspended solids (TSS), together with the metals, hydrocarbons, phosphorus, nitrogen, and other surface water pollutants that cling to them. The Isolator Row is easily accessed via a closely located manhole, and can be cleaned out with standard sewer-cleaning equipment.

Natural SuDS need maintenance too

Natural SuDS, as well as engineered ones, also need regular and planned maintenance. These range from frequent interventions such as litter picking and inspection of inlets and outlets to more occasional and seasonal activities such as vegetation management and removal of silt build-up.

Again, failure to maintain natural attenuation components such as ponds can have negative impacts. A 2018 study of SuDS in East Kilbride by the University of Glasgow, published in The Glasgow Naturalist, found that pollutants in some SuDS ponds were hindering amphibian breeding and development and that more frequent monitoring and management would be wise.

Whether natural or engineered SuDS, or a combination, maintenance regimes and their associated cost, should not be a barrier to their implementation. However, it is important that maintenance issues are understood, planned and communicated at the earliest stages of a project.

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.

Advanced Drainage Systems UK seeks to minimise SuDs maintenance

Designers need a better understanding of the maintenance requirements of different SuDS components to ensure that the systems they design will perform as intended, Advanced Drainage Systems UK manager Stuart Crisp, reports.

The issue of SuDS maintenance has always been a thorny one. Research suggests that the question of responsibility for the maintenance, and the cost of it, has been a prime factor in their slow uptake in the UK.

With the government’s intention to implement Schedule 3 of the Flood and Water Management Act 2010 in England, making the installation and adoption of SuDS mandatory, concerns about

maintenance issues have again come to the fore. Developers, designers and installers need to understand the maintenance implications for alternative solutions considered for a project and then offered to the adopting body responsible for the long-term operation of the SuDS asset. These are in addition to, for example, hydraulic performance, structural integrity and water quality. For underground attenuation devices, these vary significantly.

The impacts of poor maintenance regimes and difficult to clean systems can be significant, increasing the risk of blockages – leading to loss of capacity and flooding – and pollutants washing out into water bodies.

Guidance

The SuDS Manual, Ciria C753, recognises that underground attenuation crates are “difficult to clean” and that their capacity will reduce over time. Section 21.5.3 of the manual recommends that the size of crates should be increased by 10% to allow for accumulation of sediment. This applies even when a maintenance programme is deployed, since it is not always possible to remove all sediment during cleaning. Commercial developments, high density residential development, car parks and highways face the highest potential loss of storage, according to the guidance.

For crates and large diameter pipes, some form of silt separation and removal system upstream is normally required to slow down the rate of sediment build up and to remove some of the pollutants that cling to those particles. These upstream components must also be inspected and cleaned at intervals prescribed in a SuDS maintenance plan.

In designing its StormTech underground attenuation device, ADS sought to remove the need for costly upstream pre-treatment. An inbuilt “Isolator Row” – essentially modified StormTech elliptical arches –

collects the sediment before the water moves into the main body of the system.

Independent tests have demonstrated that the Isolator Row removes more than 80% of total suspended solids, together with the metals, hydrocarbons, phosphorus, nitrogen and other surface water pollutants that cling to them. The Isolator Row is easily accessed via a closely located manhole, and can be cleaned out with standard sewer cleaning equipment.

Natural SuDS need maintenance too

Natural SuDS, as well as engineered ones, also need regular and planned maintenance. These range from frequent interventions such as litter picking and inspection of inlets and outlets to more occasional and seasonal activities such as vegetation management and removal of silt build up.

Again, failure to maintain natural attenuation components such as ponds can have negative impacts.

A 2018 study of SuDS in East Kilbridge by the University of Glasgow published in The Glasgow Naturalist, found that pollutants in some SuDS ponds were hindering amphibian breeding and development and that more frequent monitoring and management would be wise.

Whether natural or engineered SuDS, or a combination, maintenance regimes and their associated costs, should not be a barrier to their implementation. However, it is important that maintenance issues are understood, planned and communicated at the earliest stages of a project.

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.

Designing for Water Quality Using Mitigation Indices

Now there are verified mitigation indices for engineered components says Stuart Crisp, UK manager at Advanced Drainage Systems (ADS).

The publication of the Plan for Water by the Department for Environment, Food & Rural Affairs (Defra) in April this year signalled the Government’s intention to tackle water pollution. Clearly, one of the ways to do this is by using a well-designed SuDS management train which considers both water quantity and quality, deploying SuDS components that are appropriate for the levels and types of pollution present in the surface water.

This is recognised in the Plan, with reference to Schedule 3 of the Flood and Water Management Act 2010, which will make adoption of SuDS for new developments mandatory. The Government had announced in January 2023 that Schedule 3 would be finally implemented in England, as it already has been in Wales, possibly coming into force in 2024, subject to consultation.

SuDS are often thought of as a way to manage water quantity by reducing flows into sewers and hence reducing activation of combined sewer overflows (CSOs) which discharge raw sewage into water bodies. SuDS should also be designed to manage water quality directly by removing pollutants where it is carried in surface water. The CIRIA SuDS Manual, C753, prescribes a risk-based approach, setting out the expected levels of pollution for different development types and then defining how natural and engineered SuDS elements, used as a single entity or together, can be used to remove the various forms of pollution.

When it comes to engineered SuDS components, designers and specifiers can turn to British Water, the body which represents water and wastewater companies. Having published a code of practice in 2016 and a ‘how to’ guide for manufactured stormwater treatment devices in 2022, the organisation is now hosting a list on its website of engineered SuDS components which have had their pollution treatment information verified by an independent third party expert. The ADS StormTech system, with its Isolator Row – a built-in water quality treatment device – has recently been added to British Water’s list of assessed surface water treatment devices.

Types of pollution

There are four main types of pollutant that can be found in stormwater run-off: sediments, metals, hydrocarbons and nutrients. Sediments, often referred to in pollution mitigation as total suspended solids (TSS), is particulate matter including particles of soil. Metals and metal compounds can be dissolved in run-off or attached to silts and sediments in the water. Copper and zinc, which are most commonly found in surface water in the UK, can damage plants in higher concentrations.

Hydrocarbon pollution comes with run-off from roads, car parks and areas where machines operate and are maintained, due to oil and fuel spills, tyre and brake wear. Changing climate means that rainfall events are further apart but more intense, leading to higher concentrations of pollutants, as they build up for longer before being washed away.

Nutrient pollution, usually nitrogen or phosphorous based, can come from sources such as run-off from agricultural land where fertiliser has been used or combined sewer outfalls, where wastewater and surface water are discharged into bodies of water. They can lead to algal blooms, which reduces oxygen in the water and can negatively impact on aquatic habitats.

Mitigation indices

The SuDS Manual’s method for dealing with water pollution risks starts by determining pollution hazard indices for the area under consideration. In Table 26.2, the manual provides pollution hazard indices for a range of land uses and for three types of pollution: TSS, metals and hydrocarbons. So, for example, for a busy public car park such as a supermarket or hospital, the index for TSS is 0.7, for metals is 0.6 and for hydrocarbons 0.7.

The next step is to identify a SuDS treatment train that can provide the necessary mitigation indices, either a single stage or using a combination of components. The manual has a table for that too, Table 26.3. However, this table only provides indices for natural SuDS components, stating that proprietary treatment systems must demonstrate that they can address each of the contaminant types to acceptable levels.

For engineered components, British Water’s two documents – Code of Practice for the Assessment of Manufactured Treatment Devices Designed to Treat Surface Run-off and ‘how to’ guide, Applying The CIRIA SuDS Manual (C753) Simple Index Approach To Proprietary/Manufactured Stormwater Treatment Devices – provide a methodology to calculate mitigation indices for TSS, metals and hydrocarbons.

The mitigation indices for ADS StormTech’s Isolator Row are 0.8 for TSS, 0.6 for metals and 0.7 for hydrocarbons = 0.7. This means that it meets the requirements for medium pollution hazard applications and the TSS requirements of high pollution hazard applications and can be used as a combined SuDS attenuation and water quality treatment system without the need for additional components within the treatment train.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 50,000 below ground SuDS attenuation system installations using in excess of 3m units.

Originally published in Water magazine September 2023

How SuDS can help meet new Water Management requirements

In April 2023, the Department for Environment, Food & Rural Affairs (Defra) published its Plan for Water. The aim of the plan is to create a more holistic approach to water management, ensuring that there is enough water to supply the UK’s growing population, and that the water in rivers, lakes and other water bodies is free from pollution. It promises action on all sources of pollution: wastewater treatment, agriculture, plastics, urban stormwater and road run-off, and chemicals.

Public awareness and concern about water quality, and how it impacts on the natural environment and on public health, is growing fast. And stormwater is increasingly being recognised as a big issue. As rainfall events become more intense, and our ageing sewer system becomes ever more overloaded, combined sewer overflows – where wastewater is discharged into rivers and other water bodies – are being activated more frequently.

New legislation will be welcome then – which is what the Government is suggesting in its Plan for Water. Among the proposed legislation are changes to planning policy so that new developments are designed to reduce the likelihood of both flooding and water shortages. Water companies, which will have to produce Drainage and Wastewater Management Plans, could be involved in planning decisions.

The Plan also references the Government’s plans to finally implement Schedule 3 of the Flood and Water Management Act 2010, which covers SuDS approval and adoption, in England – subject to consultation. Initially announced in January 2023, this could make the inclusion of SuDS standard practice in the design, construction and adoption of nearly all new developments from 2024. It also talks about the strategic road network and how it needs to do more to prevent pollution from highway run-off discharging into our water courses (see box).

Bioswale at a development in Hampshire taken in March 2023, showing how good SuDS can be.

Multi-faceted SuDS

Well-designed SuDS can help reduce pollution in a variety of ways. SuDS should be multi-faceted, dealing with water at source to prevent activation of combined sewer overflows (CSOs) and flooding and removing pollutants to improve water quality – as well as boosting biodiversity and providing public amenity.

Good SuDS design is based on the SuDS treatment train, or SuDS management train, which sees water passing through a logical sequence of stages using different SuDS components. The treatment train should consider both water quantity and quality, with the weighting given to each dependent on predicted water volumes, flows and the levels and types of pollution.

A SuDS train should start with prevention such as reducing impermeable surfaces, to reduce run-off and removing sources of pollution. Next comes source control, where rainfall is dealt with close to where it falls by infiltration-based elements such as soakaways, rain gardens and permeable pavements. Site control sees water managed within a local area, for instance directing water to a soakaway or infiltration device and then onto an attenuation pond or tank. Finally, regional control would see a system that could handle run-off from several sites, perhaps resulting in a detention basin or wetland.

The SuDS Manual, C753, published by CIRIA, prescribes a risk-based approach to designing SuDS for water quality. If pollution risks are deemed to be low, then SuDS designers can prioritise water quantity, amenity and biodiversity. If they are medium, then all considerations must be balanced. And if they are high, water quality evaluation must take precedence, for instance on haulage yards, industrial sites, trunk roads and motorways. It should however be noted that in all cases, including medium and low pollution risk sites, appropriate mitigation should be put in place to reduce the risk of pollution.

Heavy rain causing stormwater runoff from a road in Hoghton, near Preston, Lancashire in May 2022.

There are a range of water quality treatment measures that can be included in a SuDS train. Sometimes it is possible to use a completely natural SuDS train to deal with both water quantity and quality issues. At other times, the best solution combines natural and engineered SuDS elements, or may require proprietary manufactured elements only. This could be due to high levels of pollution loading or the space available.

There are four main types of pollutant that can be found in stormwater run-off: sediments, metals, hydrocarbons and nutrients. Sediments, often referred to in pollution mitigation as total suspended solids (TSS), is particulate matter. It includes tiny particles of soil, such as silt and clay, which have been dislodged by rainwater as it passes over the run-off surfaces.

Metals and metal compounds can be dissolved in run-off or attached to silts and sediments in the water. Copper and zinc are most commonly found in surface water in the UK but there can be cadmium and other toxic metals too. Although plants require very small amounts of copper and zinc to grow, higher concentrations can be damaging to them.

Hydrocarbon pollution comes with run- off from roads, car parks and areas where machines operate and are maintained, due to oil and fuel spills, tyre and brake wear. Changing climate means that rainfall events can be further apart but more intense, which can lead to higher concentrations of pollutants from roads, as they build up for longer before being washed away. Nutrient pollution, usually nitrogen or phosphorous based, can come from sources such as run-off from agricultural land where fertiliser has been used or CSOs, where waste water and surface water are discharged into bodies of water. They can lead to algal blooms, which reduces oxygen and can negatively impact on aquatic habitats. The Plan for Water reports £2.5bn of planned and made investment in wastewater treatment works between 2020 and 2025, which it says will halve phosphorous pollution. And it promises legislation to force water companies to make upgrades to nutrient removal near protected habitats. The Government’s Environment Act 2021 set a legally binding target to reduce phosphorus in treated wastewater by 80% by 2038 compared to a 2020 baseline, with an interim target of 50% by 2028.

Recent studies carried out by Stormwater Shepherds have indicated that phosphorus pollution is not a major problem from most urban surfaces. However, well designed SuDS can help alleviate nutrient pollution where it is a problem in surface water run-off. CIRIA guide C808, Using SuDS to reduce phosphorous in surface water run-off, published in 2022, provides guidance on how to do this. It suggests a treatment train starting by maximising infiltration, followed by sedimentation and the removal of solids and finally the introduction of actively growing plants to take up some of the dissolved phosphorus.

Wildflowers in a SuDS scheme in Chorley in Lancashire.

Capturing TSS pollution should generally be the focus of water treatment strategies in SuDS design since this removes both the solid particles and any pollution clinging to them. This can be done using a natural SuDS feature, such as planting for bioretention or a swale. Manufactured components such as filtration devices, silt traps or vortex separators can also be used upstream to remove solids before water is discharged into ponds, for instance.

Removal of sediment and solids is also important from a water quantity perspective. Build-ups reduce the capacity of a water storage element, whether natural or manufactured. How and when to remove sediment should be considered at the design stage and should be part of a planned maintenance regime.

Without a means of reducing suspended solids upstream of an attenuation device, sediment build-up within the device can reduce its efficiency over time. Some recently Introduced underground SuDS

attenuation devices have their own built-in systems for intercepting solids which are fast and simple to maintain.

SuDS in the Sheffield Grey-to-Green scheme, photographed in May 2022.

Mitigation Indices

The SuDS Manual sets out a simple method for dealing with water pollution risks, requiring the determination of pollution hazard indices for the area under consideration and then matching a SuDS device with matching mitigation Indices.

In Table 26.2, the manual provides pollution hazard indices for a range of land uses and for three types of pollution: TSS, metals and hydrocarbons. So, for example, for a busy public car park such as a supermarket or hospital, the index for TSS is 0.7, for metals is 0.6 and for hydrocarbons 0.7.

The next step is to identify a form of SuDS treatment that can provide the necessary mitigation indices, either as a single treatment stage or using a combination of components. The manual has a table for that too, Table 26.3. However, this table only provides indices for natural SuDS components, stating that proprietary treatment systems must demonstrate that they can address each of the contaminant types to acceptable levels.

The mitigation indices for the natural SuDS components were compiled by a team of experts, drawing information from a selection of published papers. More recently, in 2016, British Water published a Code of Practice for the Assessment of Manufactured Treatment Devices Designed to Treat Surface Run- off. It combines the rainfall time-series data for the UK to determine an appropriate treatment flow rate based on first-flush principles and uses a combination of two test protocols – the German Deutsches Institut für Bautechnik (DIBt) and the New Jersey Comprehensive Assessment Tool (NJCAT) from the US – to create the British Water test methods.

In 2022 British Water has also published a How To Guide, Applying The CIRIA SuDS Manual (C753) Simple Index Approach To Proprietary/Manufactured Stormwater Treatment Devices, which provides a calculation methodology to derive mitigation indices for TSS, metals and hydrocarbons based on the Code of Practice, or the DIBt or the NJCAT, test results. This allows manufactured treatment products to have their mitigation indices published so that they can be considered as part of a SuDS Management Train, often alongside vegetative treatment components.

The value of water quality

One of the challenges in the delivery of well-designed SuDS treatment trains is that important elements of the train can be removed during ‘value engineering’ exercises. For instance, a design or specification may include guidance to say that sediment should be removed upstream, but this is then considered unnecessary during a ‘value engineering’ exercise and removed or compromised.

Unfortunately, decisions like this are about short-term capital cost rather than whole life cost. They don’t consider the important issues of how maintenance should be carried out, its frequency and its cost – in terms of both cash and carbon. It may also result in failure of the system to continuously provide the required performance according to the original design, throughout the life of the development. Should Schedule 3 of the Flood and Water Management Act come into legislation, maintenance and longevity issues will be brought to the fore. In Wales, where Schedule 3 has already been adopted, developers are expected to create a maintenance plan and the adopting authority will be required to carry out the maintenance for the design life of a scheme.

SABS within county and unitary authorities will be responsible for securing the means to maintain the SuDS they adopt, and it could be that the regulatory framework in England is similar to that used in Wales. As currently understood, funding will be provided by the developer in the form of a commuted sum to the SuDS Approval Body (SAB) at the point of handover. The timeframe for the enactment of Schedule 3, and the many other pieces of proposed legislation for the Plan for Water, remains uncertain – not least due to the uncertainty over when the next general election will be held. However, the urgent need to address water quality issues will only move up the political agenda.

Incorporating SuDS trains that manage both water quality and quantity into new developments does not necessarily have to increase capital costs. Good design can reduce costs over the lifetime of the SuDS and the development.

Highway run-off

Pollution due to road run-off is a major problem in the UK. There are estimated to be over one million drains and outfalls from the strategic road network and local authority roads, the majority of which run straight into rivers and other water courses with no measures to treat the pollution in the water before they do.

The result of this is a build-up of toxic pollution in riverbeds, water, fish and other aquatic life. Run-off from roads contains high amounts of suspended solids which sit on the bed of a watercourse, bringing with them other pollutants which are released over time. Pollutants include polycyclic aromatic hydrocarbons (PAH), metals and microplastics from brakes and tyres.

Only 4,000 out of 26,000 outfalls and soakaways from the Strategic Road Network, run by National Highways in England, have measures in place to treat pollution. The Environmental Permitting Regulations say that highways authorities can discharge road-run off into water bodies only if it doesn’t cause pollution. However, the Environment Agency has never required a road authority to apply for a permit where polluted road run-off is discharging straight into rivers and other water bodies.

The Plan for Water does mention this issue, but there is no firm plan for action when it comes to road run-off. Instead, it says that it is “considering actions to take to reduce the impacts of the Strategic Road Network on water quality as part of developing the next Road Investment Strategy.” The Government will also consider ‘targeted action’ for roads owned by local authorities whose road run-off is contributing to pollution. This falls short of the urgent action which the House of Commons Environmental Audit Committee (EAC) called for in its Water Quality in Rivers report, published in January 2022. One of its suggestions was that the Environment Agency should require discharge permits for any road with annual average daily traffic above 15,000 vehicles.

National Highways has a target of improving 17.5km of water bodies every year.

The plan reports that to date National Highways has delivered over 30 water quality initiatives which have improved just under 20 miles (32km) of water bodies. In 2020-21, its annual report said it had improved 17km of waterbody, so it appears to be missing its targets. There are a number of ways that run-off from roads can be treated for pollution before it enters a water body. SuDS can be used as part of the water treatment train.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 50,000 below ground SuDS attenuation system installations using in excess of 3m units.

Originally published in Drain Trader magazine June 2023

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.

SuDS tips #4: Water Quality Management Solutions

A qualified civil engineer, Stuart Crisp has been at the forefront of construction and a specialist in drainage systems for over 35 years. He has contributed to the development of numerous British and International Standards and industry specifications and was a member of the project steering group for CIRIA C753 The SuDS Manual. In this regular series of articles, Stuart considers the different challenges facing designers and installers of below ground SuDS attenuation systems. This month covers water quality management.

Water Quality Management – mitigating the impact of pollutants in surface water runoff to prevent harmful discharges into the environment – is one of the fundamental principles of SuDS Best Practice. Essentially, this covers three key material groups:

- suspended solids – silt and other particulate material flushed off the drainage catchment surface

- hydrocarbons – oil and petroleum-based materials deposited (or spilt) on the ground, usually as a result of vehicles and machinery in operation, or worked on, in the vicinity.

- Metals – a range of metals-based materials that can cause harm to the environment, including copper, zinc, lead.

Increasingly, Water Quality Management is a key focus for SuDS systems. Planners are looking to provide “nutrient neutrality” i.e., reducing existing sources of nutrient pollution to mitigate the nutrients generated by new development. In these more demanding cases, removal of additional substances such as compounds of phosphorous and nitrogen are often required.

It is the job of key stakeholders in the Project Team to ensure that the water quality discharge meets the requirements of legislation, client, and the local environmental regulator.

Numerous reference sources exist that can help users determine the most appropriate water quality mitigation measures for a specific project. These include the CIRIA publication C753 The SuDS Manual. Chapter 4 deals with Designing for Water Quality and Chapter 26 deals with Water Quality Management. Chapter 14 relates to Proprietary Treatment Systems. Other Chapters provide guidance on specific vegetative “soft” SuDS components such as Detention basins, Swales, Infiltration systems and Filter strips. Vegetative SuDS are generally regarded as preferable in terms of SuDS Best Practice, as they are surface based solutions that manage rainfall closest to where it lands, also referred to as “source management”. Like any system, vegetative SuDS will require maintenance to ensure that they meet their design function throughout the lifetime of a development.

Designing an effective below ground SuDS attenuation system that meets the demands of both flood risk mitigation (Water Quantity Management) and pollution risk mitigation (Water Quality Management) requires a Management Train approach, where proprietary Water Quality Treatment device(s) are usually installed upstream of the below ground Attenuation Tank. This would typically require a sediment capture system, which may be as basic (and potentially inadequate?) as a catch pit or more appropriately, a proprietary gravity separation sediment tank or hydrodynamic separator. Hydrocarbon removal will require a bypass or full-retention oil/water separator, depending on the intended use of the development and the level of risk of hydrocarbon pollution.

Below ground attenuation systems such as crates and pipes offer little in the way of water quality treatment capability, so the demands of water quality must be covered by separate, additional SuDS components elsewhere in the system.

Not only can this require significant capital investment in the treatment system (each manufactured treatment device can cost >£10k, and multiple units may be required on a project), there is an additional operational cost in terms of inspection and maintenance. Failure to properly maintain water quality treatment systems can lead to problems with the attenuation tank, such as sedimentation within the tank, resulting in reduced storage volume– causing the system to fail hydraulically – and the possibility that pollutants are flushed downstream, resulting in water quality breaches and fines.

Some systems, however, include an integrated solution. New to the UK, the ADS StormTech stormwater attenuation system incorporates the unique Isolator Row, a patented, built-in water quality treatment device designed to remove silt and other polluting material flushed off the surface during rainfall.

Isolator Row has 2 treatment stages, contributing to the overall efficiency of the system. These include initial gravity separation of the silt and particulates within the Isolator Row chamber and filtration through a layer of woven geotextile fabric on the bed of the chamber, laid over a stone foundation. Two further treatment stages can take place within the stone embedment surrounding the StormTech chambers. As flow passes through the system, pollutants can adsorb onto the face of the stone, meaning that they are “trapped” and prevented from passing through to the discharge point. This material can provide nutrient for bacteria and over time, will be broken down into harmless, non-polluting material.

The four treatment stages of a StormTech system:

- Gravity separation (sedimentation) Isolator Row (2 stages)

- Filtration

- Adsorption Embedment stone surrounding StormTech system

- Biodegredation

Isolator Row has been independently tested by universities and respected industry bodies (including NJCAT) and validated to remove over 80% of Total Suspended Solids (TSS) plus metals, hydrocarbons, phosphorus, nitrogen, and other surface water pollutants.

Where nutrient neutrality is sought and there is a demand for higher levels of pollutant removal, or where more challenging pollutants need to be dealt with, other water treatment solutions may be required. These can include proprietary filtration systems designed specifically to address certain chemical species and material phases within the surface water runoff. In these situations, when considering a proprietary manufactured treatment device, it is recommended that advice is sought directly from the manufacturer.

For practitioners in the UK, it may be helpful to refer to the British Water Code of Practice: Assessment Of Manufactured Treatment Devices Designed To Treat Surface Water Runoff. This publication sets out an assessment method to measure pollutant capture and retention. Additionally, read in conjunction with the Code of Practice and the CIRIA SuDS Manual, it is possible to derive mitigation indices using the British Water How To Guide: Applying The CIRIA SuDS Manual (C753) Simple Index Approach To Proprietary/Manufactured Stormwater Treatment Devices.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine June 2022