Blog Archives

SuDS design & water quantity: back to basics

SuDS design and water quantity: back to basics

The purpose of SuDS – sustainable drainage systems – is to mimic nature. But should that automatically mean that we only consider nature-based solutions, asks Stuart Crisp.

The weather so far this year has provided a stark reminder of the challenges we face due to heavy and intense rainfall. In January, Storm Henk brought a month’s rainfall in four days to some areas, leading to flooding, the worst of it in the Midlands. And in April, the impacts of Storm Kathleen and Pierrick caused flooding across the country, especially on parts of the south coast.

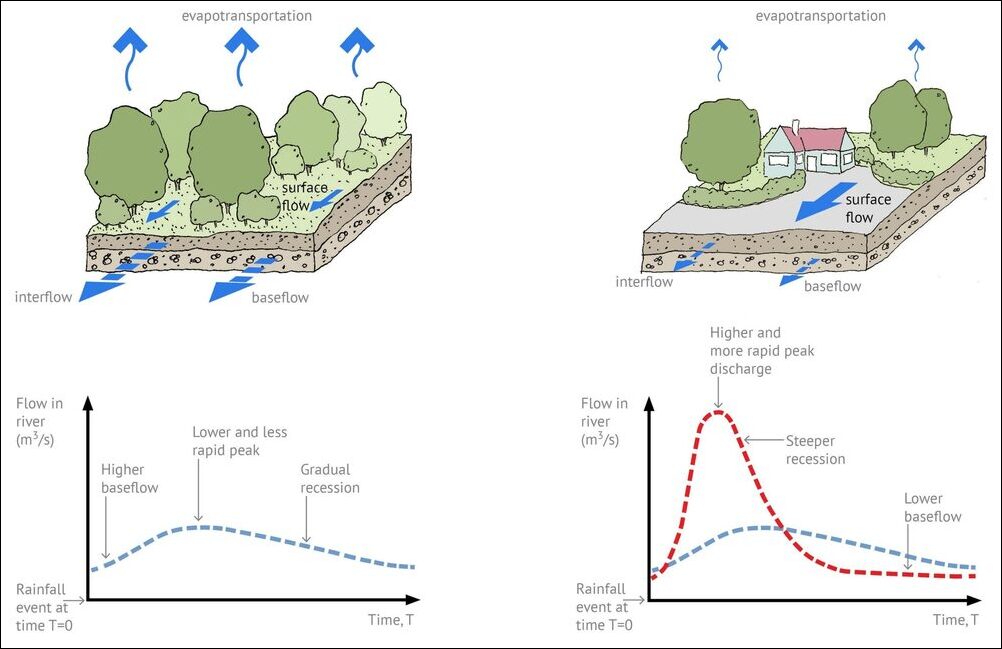

Much of this flooding is exacerbated by urban development. By replacing green fields and vegetation with hard surfaces – roads, roofs and driveways – we change the way and rate at which surface water flows out of an area or catchment.

A good SuDS design for water quantity aims to mimic the flows of water from developed site so that they are as close as possible to what would have happened, had there still been a greenfield site there. That means throttling the flow of water – in other words providing storage and releasing it later, more slowly – so that it is not rushing so quickly into sewers and water courses and overwhelming them, leading to flooding.

Many policy documents from organisations that currently adopt SuDS – typically Scottish Water in Scotland, the county or unitary authority in Wales or a water company in England mandate natural or green SuDS, often prohibiting the use of proprietary or grey SuDS.

While green SuDS, such as swales and ponds are the right solution for some developments, a blinkered approach may not best mimic nature, could ramp up capital costs and potentially lead to longer-term problems and higher maintenance and operation costs.

Although designing for water quantity and the urgent need to reduce the risk of flooding is vital, there are the other pillars of SuDS to think about too: water quality, amenity and biodiversity. Previous articles in Drain Trader’s June 2023 and February 2024 issues, looked at water quality issues and what type of management trains were best suited to different types of development, depending on pollutant loads.

Operational and maintenance costs for SuDS schemes are often overlooked and ignored, but the promised implementation of Schedule 3 of the Flood and Water Management Act 2010 in England will shed a harsh light on these. SuDS Approval Bodies (SABs), likely to sit within local authorities, will require robust information about inspection and maintenance regimes and expected costs over the lifetime of a development.

An article in Drain Trader’s March 2023 edition looked at why poorly thought-out SuDS can lead to shorter service lives and higher operational costs than those expected from the design.

Mimicking nature

On a greenfield site, the first 5mm of rain would not typically generate surface runoff, it would infiltrate into the ground, evaporate or transpire through the leaves of plants. Then, when water flows from the surface of a catchment and exceeds the capacity of the receiving water body, the additional volume of water would spill over onto the floodplain.

When we develop on that catchment to add impermeable surfaces, such as roofs, roads and hardstandings, the amount of surface water runoff generated can increase dramatically. In a dense, urban environment, 95% of the rainfall could flow off the catchment as surface runoff, increasing the volume of water that reaches water courses or sewers. It is also likely that the peak flow will be higher and come sooner, than had it remained a greenfield site.

CIRIA C753 The Suds Manual gives a graphical illustration of this. Figure 3.1, in Chapter 3 which deals with design for water quantity, shows hydrographs for the discharge rates of surface water for an area in three situations: when it is greenfield; when developed without flow attenuation; and when developed with flow attenuation. (Figure 1 shows a similar graph, courtesy of SUSDRAIN).

The amount of water that a SuDS system will need to attenuate or store, and the rate at which the water should be discharged is the subject of the hydraulic design for that system. For those that want to go back to first principles, these are set out in BS EN 16933-2 Drain and sewer systems outside buildings – Design – Part 2: Hydraulic design.

Today, however, many drainage engineers rely on software such as InfoDrainage and MicroDrainage (AutoDesk/Innovyze), Flow (Causeway) and Site3D. But this ‘black box’ approach to calculations can mean that designers don’t have the opportunity to properly understand the assumptions and coefficients that have been used – and the impact on water quality based on the SuDS components selected to satisfy the hydraulic design – which may lead to a suboptimal design.

In a SUSDRAIN factsheet from March 2014, Assessing attenuation storage volumes for SuDS – another useful resource for designers – author Anthony McCloy explains the risks of this approach:

“Don’t expect exact answers from the calculation process, it is a usable approximation that can provide acceptable solutions for design. Most of the inputs are based on statistics and calibration factors; therefore we can only ever achieve an approximation of how the system will behave in reality. The results of calculations and modelling need to be used alongside professional judgement to provide the design.”

Ten years later, this point is just as relevant as ever, perhaps even more so as design software is more widely used, with newer generations of engineers never called on to design from first principles. McCloy also advises that those assessing potential SuDS, such as SABs, must also have a basic understanding of first principles of storage volumes and hydraulic design so that they can carry out their statutory duties.

Water storage toolbox

There are many ways that we can create storage for excess surface water. Storage can be online, meaning that flow enters the element, passes through and out the other side or offline where flow enters and exits via the same point. A design could include both online and offline storage where, for example, flow above the 1-in-30-year return period is directed offline to accommodate the 1-in-100-year event.

Vegetative or surface-based solutions include ponds, detention basins which are dry until excess water needs to be accommodated and swales which can be used to accommodate volume, as well as to communicate flow between SuDS elements and for infiltration.

Ponds can be an attractive choice, potentially ticking boxes for all the four pillars of SuDS. From a water quantity perspective, they must have sufficient capacity to cope with rising water levels during higher rainfall events throughout their design lives. Any sediment entering the pond will settle out quickly, since the sediment particles soon reach terminal velocity allowing them to settle to the bottom of the pond.

As an asset owner or adopter, it is important to anticipate the amount of sediment that will settle out over time, because the accumulated sediment must be somehow removed at intervals to allow the pond to provide sufficient storage volume. One issue that is sometimes overlooked in the design of ponds is providing safe and cost-effective means of accessing the pond to remove sediment when required.

A recent story from Gloucestershire illustrates the costs involved. Local residents petitioned Gloucester City Council in January this year to desilt Saintbridge pond in Abbeydale because it produces a foul smell in the summer and the silt is negatively impacting on water quality and habitats. The council refused, saying that it was only 15 years since it last desilted the pond and that the operation would cost £700,000.

Commenting on the story, Jo Bradley, director of operations at Stormwater Shepherds, pointed out the error of not having installed an upstream sediment separator at the same time as the pond. “If a manufactured sediment separator had been included, it could have been emptied every year, costing maybe £700 – £1000. That would have cost up to £20,000 over the 20-year cycle and avoided the £700,000 cost that they are now facing.”

Bradley pointed out that by bringing in heavy plant every 20 years, removing vegetation and sediment, the pond’s habitats and inhabitants are disturbed, negatively impacting on nature. And she added that the sediment in the pond could well be contaminated with toxic, bio-accumulative pollutants and tyre-wear particles.

CIRIA’s manual says that a sediment separator or sediment forebay should be installed upstream of every pond. And, depending on the pollutants likely to be washed into the pond with the surface water, other pre-treatment could be needed. Without this, there is a danger that wildlife will be attracted to the pond, only to suffer damage.

This point was illustrated by researchers at Glasgow University, who compared SuDS ponds with natural ponds and found that pollutants were higher in some of the SuDS ones, negatively affecting amphibian breeding and development. A paper published on the research issues this warning: “The function of SuDS and other urban drainage systems to sequester pollutants increases their potential to be ecological traps by advertising false cues of suitable habitat.”

Proprietary attenuation

The most commonly used proprietary solutions include permeable paving, where the water passes through the gaps between blocks to be stored in unbound granular material below them; geocellular crates which are buried below ground; and large-diameter pipes below ground. There are also innovative systems, new to the UK, such as arch-shaped chambers which combine both filtration and attenuation without the need for additional upstream devices.

Permeable block paving can be useful because it requires a limited volume of excavation. In terms of water quality, block paving provides two stages of water treatment: water is filtered as it passes through the gaps between blocks and pollutants can then be broken-down by bacteria naturally present as it passes through the granular fill beneath it and then either infiltrates the ground or flows into another part of the system.

The capacity of permeable paving to accommodate surface runoff decreases over time. And regular maintenance is needed to clean out the joints between the paving blocks so that they do not become clogged up, making sure that the wash water does not enter the drainage system served by the permeable pavement. Also, note that water companies do not adopt permeable paving as it is not only a SuDS component, but also a structural pavement.

Geocellular crates can be a good choice if there is a limited plan area for water storage, since they provide a large volume for a limited footprint. They are typically manufactured from polypropylene (PP) or PVC by injection molding, or extrusion of joining thermoformed sheets.

Crate-based systems are relatively simple to design and due to their lightweight and modular construction, they are easy to install. There are a variety of types on the market, from shallow sub-base replacement systems to be used beneath car parks to crates which can be used at a greater depth for higher volumes of storage.

However, crates are likely to decrease in storage capacity over time. Installation of catchpits, silt separators and other sediment pre-treatment measures upstream are required – but often under-designed, which can lead to issues as maintenance to remove sediment build up in crate-based systems can be difficult or impossible. There are also question marks over their long-term durability, as some crates do not comply with the latest industry specifications for structural integrity.

Clause 21.5.3 and Table 21.2 of the SuDS Manual suggests adding an additional 10% to the storage volume of crates to account for sediment build up. Asset owners and adopters of SuDS systems should determine if a crate-based system has been appropriately up-sized by 10% and if not, that the SuDS designer or manufacturer has provided evidence to demonstrate that all the sediment can be removed from the crate-based system. Not all adopting bodies will accept crates.

Large diameter pipes, laid as a single run or in parallel, with manifolds are an established solution, one of the forerunners of proprietary underground water attenuation which can be created from existing products. They can be a cost-effective choice with concrete and plastic the most commonly used materials; thin steel pipes and a hybrid plastic and steel product are other choices.

A downside to large-diameter pipes is that they are larger and can be heavier to transport and install, requiring more transport movements for delivery, more storage space on site and a larger excavation footprint. Depending on the type of pipe material, they may not be adoptable by some asset owners.

Innovative underground water storage systems such as arch-shaped chambers are simple to design and install and can be configured to fit irregular areas or to fit around existing infrastructure or obstacles. Their arch shape means that the embedment material around them is shaped into ‘stone columns’ allowing them to be installed at shallower depths, while taking heavier loadings. They are lightweight and stackable which means they are easy to transport, store and install.

One proprietary brand of arches, StormTech, can be installed with an integrated pre-treatment element, Isolator Row, which takes out sediments and other surface water pollutants from the first flush of a rainfall event. The inclusion of Isolator Row can remove the need to install upstream pre-treatment devices such as sediment traps and bypass separators, resulting in considerable cost savings. StormTech has been designed for ease of maintenance, since only Isolator Row needs to be cleaned, accessed from the manhole using standard sewer cleaning equipment.

This brand of arches provides four stages of water treatment: Isolator Row provides the first two stages. Sedimentation – gravity separation of the silt particles, settling out on the bed of Isolator Row – and filtration, as the water passes through a layer of woven geotextile fabric.

The next two treatment stages are akin to that for permeable concrete block paving; that is adsorption as the water passes over the granular material surrounding the chambers and biodegredation from the action of bacteria breaking down pollutants into non-polluting material. StormTech meets the requirements for adoption by water companies as set out in the Design and Construction Guidance (DCG) for adoptable sewers.

Green and grey

Attenuation of surface water in vegetative SuDS can be a good solution for some developments, particularly where there is lots of space and low pollutant loads. But insisting that they are the only choice could lead to designs which do not best mimic nature or provide the best options.

A more flexible approach to SuDS would allow a combination of green and grey elements to be deployed. This could allow some water to be stored in green SuDS such as ponds and swales, with proprietary solutions such as below-ground pre-treatment devices and attenuation chambers, deployed elsewhere. Alternatively, crates or arched chambers could be installed as additional storage beneath a smaller pond or under a parking area to deliver multiple SuDS benefits within a smaller available footprint.

A good SuDS design also factors in the cost and ease of maintenance of the various SuDS elements. There is a misconception that natural SuDS can be left to nature, but this is not the case. Vegetation needs to be maintained, litter must be picked at frequent intervals and for ponds, sediment build-up needs to be removed, as explained above, to maintain the capacity of the pond.

Equally for proprietary SuDS elements, maintenance to preserve the hydraulic capacity of water storage and the functioning of water quality treatment devices is an important consideration. When products are substituted in ‘value-engineering’ exercises which are, in fact, capital cost reduction exercises, the impact on water quality is often overlooked. Although pollutant loads could look low enough that upstream treatment is not needed, there will be a need to consider the long-term performance of the SuDS system over the lifetime of the development.

Finally, there is the issue of climate change. Although SuDS designs do apply factors to account for increasing rainfall intensity and frequency, they do not consider the fact that more intense periods of rainfall increase the amount of sediment and pollutants that are swept along with surface water. Add an extended dry period before that rainfall event, and the problem will be worse.

To limit designers to vegetative SuDS is to limit the choice of tools they have available to them. With a bigger toolbox of grey and green SuDS elements, they have a greater opportunity to create solutions that are technically, environmentally and economically viable over their entire lifetimes.

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.

Crate Expectations

With strengthening focus on flooding and water quality, CIRIA’s advice to oversize crate-based attenuation tanks by 10% has never been more relevant, says Stuart Crisp, UK manager at Advanced Drainage Systems (ADS).

There’s a reason why the CIRIA SuDS Manual C753 suggests that “difficult to clean” SuDS attenuation systems, such as below-ground crates, should be oversized by 10%: there is a risk that sediment will build up in them, reducing their storage capacity.

With increasing legislation to manage flood risk and to prevent pollution, and more intense rainfall events, this advice becomes even more pertinent. There is a higher volume of water for SuDS devices to deal with and, when these events follow dry spells, more particulate matter and pollutants are swept along with surface water.

Unfortunately, this need to upsize crate-based attenuation tanks by 10% is often overlooked, thanks to focus on originally calculated target storage volumes. Furthermore, if the development is ‘value-engineered, the capital cost saving also often focusses on the original target storage volume. Up-sizing is often disregarded and, if the design is substituted for another type of attenuation system, the implications for water quality and the effectiveness of the treatment train are ignored.

The result is an increased risk of flooding and an increased risk to water quality.

Risk-based approach

The SuDS manual suggests a risk-based approach to designing SuDS management trains. Considering sediment, this means assessing: how much is likely to build up, depending on the location, how that load might change over time, and how often and easily devices will need to be cleaned.

Clause 21.5.3 of the manual explains the rationale for upsizing below-ground attenuation by 10%, while Table 21.2 shows the potential loss of storage capacity. Typically, commercial developments suffer from the highest sediment loading, followed by car parks, high-density residential developments and highways.

Removing sediment is also necessary to protect water quality and to avoid the negative impacts of pollutants. The predicted type, quantity and concentration of pollutants governs the choice of natural or manufactured SuDS element that would be most suitable.

Some underground attenuation systems, such as ADS’s StormTech arched system with its Isolator Row, are designed with in-built treatment systems which can be easily cleaned using standard equipment. This can negate the need for – and cost of – upstream treatment devices, while still protecting attenuation capacity and water quality.

Pay now or pay later

With the anticipated implementation of Schedule 3 of the Flood and Water Management Act 2010, SuDS adopting bodies will be looking hard at maintenance issues. Asset owners will need to be assured that the SuDS they are taking on will perform as designed throughout their whole lives.

Short-term savings in capital cost, which skimp on capacity and compromise water quality, can lead to long-term problems and greater whole-life costs, resulting in higher commuted sums for developers and an additional, avoidable cost burden on UK plc.

If a system is claimed to be exempt from the 10% up-sizing guidance, evidence that the system can be completely and easily cleaned should be demanded.

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.

Future-proofing for Schedule 3

With legislation mandating SuDS and their adoption for new developments on the horizon, developers and designers need to upskill to ensure future designs meet tough new standards.

The Government’s recent announcement that it intends to implement Schedule 3 of the Flood and Water Management Act 2010, is a game changer for SuDS. It means that SuDS adoption is expected to be mandatory in England, as it has been in Wales since 2019. In Scotland, Schedule 3 has not been implemented, but SuDS is generally a requirement within planning legislation.

“While developers currently have the right to connect drainage systems into sewers, that is unlikely to be the case anymore,” explains Stuart Crisp, UK manager at Advanced Drainage Systems (ADS). “Instead, they will have to show that they have included SuDS in their schemes and demonstrate how that SuDS system can be maintained over the lifetime of a development.”

Subject to a consultation later this year, implementation of Schedule 3, which includes SuDS approval and adoption, is expected in late 2024. That means that there is less than two years for concerned professionals to get up to speed with the range and implications of possible solutions, both above and below ground.

“Designers will have to think about more than just hydraulic design, to include whole life maintenance and treatment train to deal with water quality issues and specific pollutants,” says Crisp. “There will probably be a transition period as Schedule 3 comes in, but it makes sense to upskill now in order to future-proof designs.”

Currently, SuDS can be adopted by water companies as long as systems comply with the Design and Construction Guidance (DCG) which sets out how SuDS should be delivered. However, it is not compulsory for a developer to jump through the adoption hoops, leading to some assets not being of a prescribed, consistent standard of quality and performance or properly maintained and monitored, leading to problems down the line.

DCG was updated last year to include arch-shaped below-ground attenuation structures, such as ADS’s StormTech. StormTech offers a flexible and cost-efficient alternative to other below-ground attenuation structures such as crates or large-diameter pipes, with the benefit of built-in pollution treatment, reducing the extent of additional treatment elsewhere in the SuDS system.

It is expected that Schedule 3 will change the adopters of SuDS to become SuDS approving bodies (SABs) which will be within unitary councils or county councils. And it will bring in new statutory guidance, taking over from DCG to cover design, construction and operation over an asset’s lifetime.

“The statutory requirements in England are likely to be more onerous than both DCG and the current non-statutory standards in terms of what will be acceptable for planning approval and adoption after construction,” warns Crisp. “SuDS adoption becoming mandatory, with few exceptions, will raise the bar. Happily, poor quality products and poorly executed designs are likely to disappear from the market.”

For anyone looking to start the upskilling process now, manufacturer training and CPDs, such as those on below-ground attenuation offered by ADS, are already available and should include information on legislation, best practice and comparable systems.

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.