Author Archives: admin

SuDS tips #1: Below ground water attenuation systems – engineering considerations

A qualified civil engineer, Stuart Crisp has been at the forefront of construction and a specialist in drainage systems for over 35 years. He has contributed to the development of numerous British and International Standards and industry specifications, and was a member of the project steering group for CIRIA C753 The SuDS Manual. In the first in a regular series of articles, Stuart considers the different challenges facing designers and installers of below ground SuDS attenuation systems. This month, it’s the primary engineering considerations.

Most new build sites across the UK will now have a requirement for a water attenuation system in order to control stormwater that lands on the site. Before sites are built on the ground it will often naturally soak up rainfall however when new buildings are created there is nowhere for the rainfall to go. Water attenuation systems work by holding back the water in a storage vessel on site and slowly releasing the rainwater to the storm drain at a rate in which the infrastructure can handle.

Whilst there are many different types of stormwater storage and attenuation solutions: permeable block paving, geocellular crates, large diameter pipes, vaults and plastic corrugated arch structures such as ADS StormTech, not all systems provide the same attributes. Product choice is therefore central to the engineering solution. A simple designation of inflow rate, outflow rate and storage volume could result in a poorly executed project.

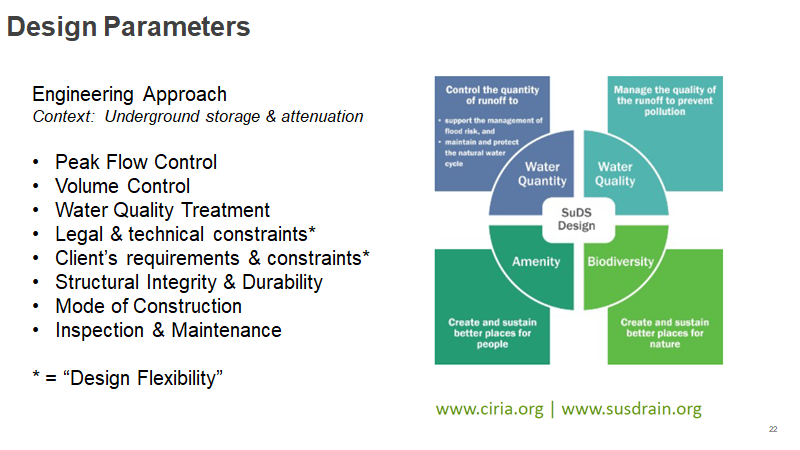

A well-designed attenuation project will not only consider the hydraulic functionality of the system (flow control and volume control), but also the fundamental principles of SuDS Best Practice, often cited as the four pillars of SuDS, i.e. Water Quantity, Water Quality, Biodiversity and Amenity.

Aligning the engineering design parameters for below ground attenuation with the four pillars of SuDS Best Practice

Consideration of these design parameters may lead to a decision to provide attenuation below ground. Cost of land is frequently the main consideration and the developer’s desire to maximise the return on their investment, although other issues such as Planning Gain and a requirement to provide parks, car parks or other civil amenities could also be a factor. In this context, it should be noted that all four pillars of SuDS Best Practice may not be achievable, although the hydraulic performance of the system is essential and must always be satisfied to mitigate against flooding.

To help achieve SuDS Best Practice, some proprietary below ground systems can provide integral water quality treatment, such as the StormTech system from Advanced Drainage Systems (ADS). This solution can contribute to the water quality requirements of the project without the need for additional expensive equipment. Other systems that are unable to provide water quality treatment may require additional SuDS components, such as separate pre-treatment for silt removal.

ADS StormTech includes Isolator Row – a ‘free’ water quality treatment device

At the design stage, a number of other limitations should be considered, such as legal and technical constraints and the client’s specific requirements. The below ground structure will become an infrastructure asset and as such it will require appropriate structural robustness and durability.

It is also vital to consider how the attenuation system will be built. The choice of system used can affect speed and cost of construction and other factors such as the number of transport movements to/from site, storage space, footprint to volume ratio, excavation and muck-away costs, minimum depth of cover, invert depth / construction depth / proximity to groundwater all need to be considered as part of the optimum design solution. Crucially – and often overlooked – is the ease of inspection and cost-effectiveness of maintenance. Sometimes, the most traditional solution in terms of hydraulic requirements, can give the client an ongoing problem in terms of effective cleaning and upkeep.

Over the coming months, we shall be taking a closer look at all of these factors and how best to accommodate them in an optimised SuDS attenuation system.

To find out more about ADS UK’s Water Attenuation Systems contact us today on 0203 442 0607 or click here.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine March 2022

StormTech helps manage Britain’s wetter weather

As British weather officially gets wetter, ADS StormTech – the world’s preferred proprietary stormwater attenuation system – arrives in the UK.

With Britain hosting the UN’s Climate Change Conference this November, the recent State of the Climate report was greeted with interest by politicians and construction professionals alike. Published by The Royal Meteorological Society, the report showed that Britain had become 6% wetter, on average, over the last 30 years (1991-2020). Additionally, six of the 10 wettest years since 1862 have occurred since 1998.

This wetter weather will challenge the UK’s drainage infrastructure and the management of water quantity and quality. Fortunately for engineers working on rainfall management and stormwater attenuation systems, StormTech – the world’s preferred subsurface water management system – is now available in the UK.

StormTech is manufactured by ADS, America’s largest manufacturer of corrugated thermoplastic drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 installations – including St Petersburg and Guernsey airports – ranging from the DC United stadium to Lidl stores in the USA.

StormTech provides a durable solution for commercial, residential, industrial and infrastructure installations. As part of an integrated SuDS system, StormTech helps provide valuable surface space for parking, playgrounds or other amenities, and has many benefits over alternatives such as geo- cellular crates, large diameter pipes and vaulted systems.

Flexibility is designed-in to StormTech. The chambers are injection moulded to ensure consistent quality and performance, and even the colour and semi-elliptical shape are deliberate engineering choices. The chambers shape the embedment stone into structural arches forming load bearing columns. This makes StormTech more adaptable than other systems, as it’s the stone that transmits the majority of the load.

StormTech chambers lock together, providing uninterrupted access for easy inspection and maintenance, and the wide range of sizes makes it easy to optimise systems for all conditions, including shallow invert depths and reduced footprints. They’re also highly adaptable and can be configured around obstacles and afford multiple inlet and outlet positions. Standard pipe manifolds, manholes, access chambers and flow controls can be used.

StormTech incorporates the unique, patented Isolator Row, a built-in water quality treatment device, removing silt, sediment and other surface water pollutants. Isolator Row has been independently tested by universities and respected industry bodies and proven to remove over 80% of Total Suspended Solids (TSS) and other water-borne pollutants including metals, hydrocarbons, phosphorus, and nitrogen. Isolator Row provides two treatment stages: settling (gravity separation) and filtration. Unlike other sub-surface systems, Isolator Row provides a “free” water quality treatment device as an integral part of the stormwater attenuation system.

StormTech’s Design Tool 2.0 provides quick and effective system design optimisation that integrates with CAD and other design, engineering and specification documents. Sample designs and layouts are available, as are a team of specialist design engineers. For installers, the SiteASSIST app includes comprehensive instructions and videos, making working with StormTech fast, easy and efficient.

StormTech affords low embodied carbon per m 3 of attenuated water compared with alternative systems and is fully recyclable. It is independently tested, BBA approved and compliant with ASTM F2787, F2418 and F2922.

Originally published in NCE.com November 2021

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.