Author Archives: jordan

Why ‘install as per manufacturer’s instructions’ is not enough

A competent design for a buried drainage structure must encompass the performance of the product itself, the materials around it and all the interactions in that system, says Stuart Crisp, UK manager of Advanced Drainage Systems (ADS).

It is common to receive drawings for buried drainage structures which simply say ‘install as per manufacturer’s instructions.’ That’s a risky strategy which does not ensure that a SuDS or other drainage system will perform as the designer intended.

When considering the structural integrity of a buried drainage product, such as below-ground SuDS attenuation assets, the designer must consider the whole system: the performance of the product itself; the embedment material and how the product interacts with it; the subgrade material surrounding the excavation and its performance; and the loadings which will be applied.

Failure to appreciate all these elements can lead, in a worst-case scenario, to failure of that structure. For instance, CIRIA C737 structural and geo-technical design of modular geo-cellular drainage systems, provides a list of the main contributing factors to most failures of such structures. The first two are: insufficient appreciation of the importance of an appropriate structural and geo-technical design; and failure to consider particular ground conditions on the site or not allowing for deformation of theunits.

CIRIA C737 underlines the fact that a competent engineer should oversee the design and installation of geo-cellular tanks or crates. And it points out that the responsible engineer should be experienced in ground engineering.

For below-ground SuDS attenuation products, the design approach will be fundamentally different, depending on the type of product deployed, whether crate large-diameter pipe or arch-shaped structure. It is also important to note that systems based around pipes behave very differently,depending on what material the pipe is made of.BS 9295:2020 Guide to the structural design of buried pipes explains that the stiffness of the native soil surrounding a pipe can be particularly important for a flexible pipe, such as a plastic one. Flexible pipes deflect on loading into an oval shape and can develop significant lateral earth pressure around them. On the other hand, pipes made from rigid materials, such as concrete or clay, do not deflect and therefore take most of the loading themselves.

Below-ground attenuation crates are subject to lateral loading, as well as to loading from above. So, the designer must factor in the type of material around the product, as well as any loading due to the presence of groundwater.

For buried arch-shaped structures, the distribution of loading is different again. The arch shape concentrates the overburden loads through the embedment stone to the spaces between the feet of the arches. The loads are then transferred through a layer of foundation stone to the native subgrade beneath.

Manufacturers should provide technical guidance related to the loading and interactions of their products with the native soil. For instance, ADS’s technical note TN6.22 StormTech Subgrade Performance Considerations does this for arch-shaped chambers.

One of the risks with buried drainage structures is that design responsibilities between the client, designer and manufacturer are often unclear which can mean that the contractor is left to select a product without sufficient information. This risk can be mitigated by a more rigorous approach in the early stages of design.

Recycled aggregate and below-ground SuDS

Recycled aggregate could be used more frequently for installation of below-ground attenuation assets, says Stuart Crisp, UK manager of Advanced Drainage Systems(ADS).

Substituting recycled aggregate for virgin aggregate helps retain natural resources for future generations and can come with cost benefits. Although there is an opportunity to do this with below-ground attenuation assets in sustainable drainage systems (SuDS), contractors often choose to go with what they know–which is the ‘safe’ route of virgin aggregates.

In specifying recycled aggregates, designers and contractors should be aware of the relevant standards, together with any technical guidance from the manufacturer of the attenuation product. BS EN 13242 (+A1:2013) sets out the properties required for aggregates produced from natural, manufactured or recycled materials for hydraulically bound and unbound materials for civil engineering works. Reputable suppliers will provide recycled aggregate with a CE mark to demonstrate conformity to the standard.

Different product manufacturers may have additional requirements for recycled aggregate which is to be used in below-ground SuDS attenuation systems to ensure that it performs its intended functions. For instance, ADS Pipe’s technical guidance for recycled aggregate for its StormTech system calls for a 20/40mm aggregate which is clean, crushed and angular, with less than 5% fines. The reason for limiting fines is that the void space between the aggregate needs to be preserved to allow for the storage and movement of the water through the matrix of aggregate.

Specifications should set out an average porosity for the aggregate. Porosity is the volume of voids over the total volume; this is sometimes confused with void ratio which is the volume of voids over the volume of solids which can lead to installed systems not meeting design requirements.

Other factors to consider when selecting recycled aggregate include the nature of the ground and the ground water and whether there are any potentially aggressive substances present. Sulphites carried in ground water, for example, could react with recycled concrete aggregate and degrade it over time.

Different types of below-ground attenuation systems require different proportions of aggregate to manufactured product. Crates deploy small amounts of aggregate around their perimeter, large-diameter pipes and arch-shaped attenuation products use a greater proportion of aggregate.

With arch-shaped attenuation products, the aggregate around the arches has a dual purpose. It provides structural support, with the elliptical shape of the arches forming the aggregate around them into stone arches and structural columns, transferring the loads away from the chambers into the stiffer material surrounding them. The aggregate also provides additional storage volume which contributes to the efficiency of the attenuation system in terms of its water storage capability.

Recycled aggregate will not necessarily have lower embodied carbon than virgin aggregate, which tends to be supplied from quarries close to the point of installation.

Recycled aggregate can come at a lower cost than its virgin counterpart, again depending largely on transportation distances.

Generally speaking, attenuation products requiring a higher aggregate-to-product ratio tend to have a lower overall carbon footprint per cubic metre of storage than those requiring less aggregate-to-product.

Underground SuDS: derisking the future with standards, certifications andapprovals

Anyone involved in the design, installation or adoption of below-ground SuDS attenuation assets should be doing their due diligence to ensure they are fit for purpose, says Stuart Crisp of ADS.

Below ground attenuation devices for sustainable drainage systems (SuDS), such as crates, are often considered a commodity. The tendency can be to fit the lowest cost option, given the volume of water required by the engineer’s design.

This may function very well on day one. But how can the ultimate asset owner be sure it will function as intended 10, 20 or more years down the line?

This is the question that any SuDS adopting body will be asking, when Schedule 3 of the Flood and Water Management Act 2010 comes into force in England, making SuDS for new developments mandatory. SABs must assess what maintenance and repair costs might be, in order to agree the commuted sum that a developer pays when handing over the asset.

An important part of the due diligence required for below ground SuDS attenuation devices is to check that the products selected meet all the necessary standards, certifications and approvals. To do that properly, it is important to deep dive into the detail of how manufacturers claim that their products comply.

Standards and certifications.

The starting point for any construction product to be used in the UK is that it must, bylaw, have a CE mark or a UKCA mark–although the date from which the UKCA mark will be required has recently been pushed back from June 2025 for at least two years. Next, products must conform to the relevant standards in terms of both functional performance-which is governed mainly by the evaluation, management and testing of the product’s material properties, manufacturing processes and dimensional tolerances–and the structural design process. These two distinct requirements can sometimes be found in two different standards or alternatively in separate parts of the same standard, depending on the product type and material.

British Standards (BS) are the most well known in the UK but in some cases, a harmonised standard, accepted by multiple nations, could apply, which would be designated BS EN or BS ISO in the UK. Note that there cannot be more than one standard covering the same scope in any territory.

For innovative solutions, where a product standard does not exist, manufacturers must take a different approach.

Some choose to cherry pick clauses from different standards in an attempt to demonstrate fitness for purpose, but this is not a reliable approach.

The responsible route is to put the product through an evaluation conducted by a recognised certification body such as the British Board of Agrément (BBA), Water Research Centre (WRc) or British Standards Institution (BSI). This process effectively assesses the key elements that a standard would cover, and checks that the product meets the claims of the manufacturer.

Given the rigour of the testing and checking involved, such approvals understandably take some time to process. ADS was delighted to formally receive its BBA certification for its StormTech range of arch-shaped below ground SuDS attenuation devices in November this year.

Approvals

Across the UK, there are a range of different asset owners that approve SuDS. In England, water companies require developers to follow OFWAT’s Design and Construction Guidance (DCG) for sewers. In addition, the Lead Local Flood Authority (LLFA) must also evaluate and approve drainage designs.

In Scotland, Scottish Water is the adopting body, and SuDS must meet the requirements of Sewers for Scotland 4th edition. The Scottish Environment Protection Agency (SEPA) must also be satisfied that the treatment train is adequate to protect water quality.

In Wales, Schedule 3 of the Flood and Water Management Act was adopted in 2019. The requirement of SABs is based on the Welsh Government’s Statutory Standards for Sustainable Drainage Systems (SuDS) and the CIRIA SuDS Manual, C753.

In a small number of cases, independent adoption bodies such as Icosa Water and Independent Water Networks (IWNL) may take on responsibility for SuDS maintenance. Their requirements are likely to be a version of the DCG.

For devices installed to serve a highway, there is a separate need to demonstrate compliance. For the strategic road network, National Highways’ Design Manual for Roads and Bridges (DMRB) is the most significant document, with local highways authorities often following suit. Products not recognised within National Highways’standards can be used through the Departure from Standards process.

Of course, the compliance requirements touched on in this article are just one part of the due diligence process for SuDS. Below ground attenuation devices can be rendered unfit for purpose due to other parts of the SuDS system such as inadequate treatment capability, or poor maintenance regimes. Systems such as StormTech,where water treatment comes as an integral part of the device, can provide a straightforward way to alleviate that risk.

SuDS design and water quantity: back to basics. Part I. – November 2024

In this, the first of a two-part series considering the fundamentals of SuDS, Stuart Crisp, UK Manager, Advanced Drainage Systems asks if nature-based solutions are an automatic choice when specifying SuDS designed to mimic nature.

The weather so far this year has provided a stark reminder of the challenges we face due to heavy and intense rainfall. January’s Storm Henk brought a month’s rainfall in four days to some areas, leading to flooding, the worst of it in the Midlands. And in April, the impacts of Storm Kathleen and Pierrick caused flooding across the country,especially on parts of the south coast.

Ten English counties experienced their wettest September on record and for Bedfordshire and Oxfordshire, September 2024 was the wettest calendar month the counties have experienced, in a series dating back to 1836.

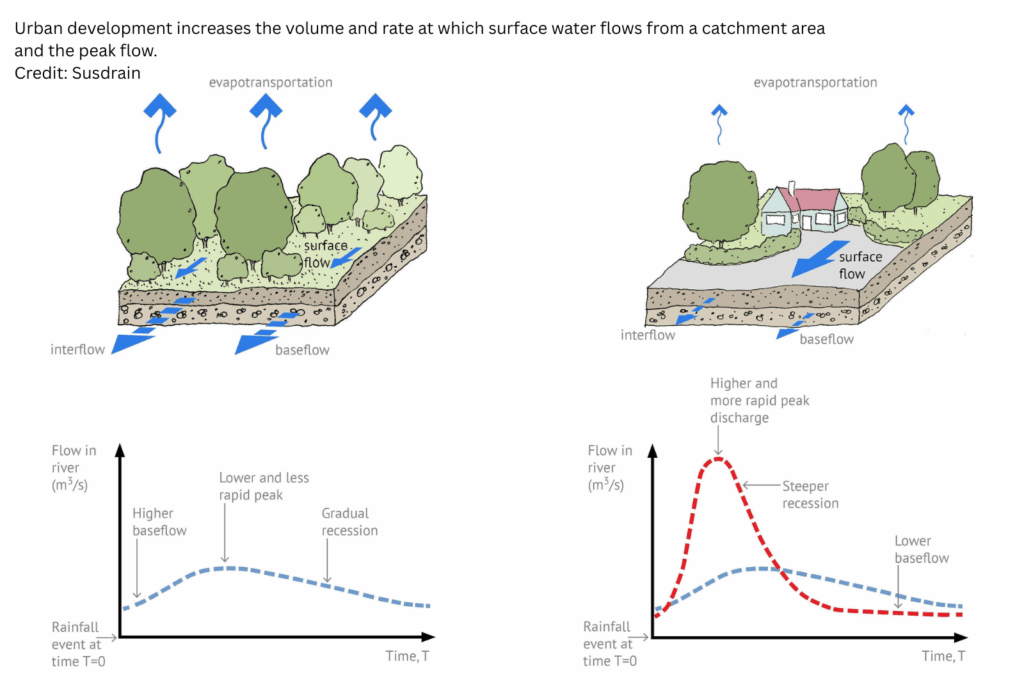

Much of this flooding is exacerbated by urban development. By replacing green fields and vegetation with hard surfaces–roads, roofs and driveways–we change the way and rate at which surface water flows out of an area or catchment.

A good SuDS design for water quantity aims to mimic the flows of water from developed sites so that they are as close as possible to what would have happened,had there still been a greenfield site there. That means throttling the flow of water–in other words providing storage and releasing it later, more slowly–so that it is not rushing so quickly into sewers and water courses and overwhelming them, leading to flooding.

Many policy documents from organisations that currently adopt SuDS–typically Scottish Water in Scotland, the county or unitary authority in Wales or a water company in England mandate natural or green SuDS, often prohibiting the use of proprietary or grey SuDS.

While green SuDS, such as swales and ponds are the right solution for some developments, a blinkered approach may not offer the optimum solution; capital costs could ramp up, it may fail to provide the lowest environmental impact and potentially lead to longer-term problems and higher maintenance and operation costs.

Although designing for water quantity and the urgent need to reduce the risk of flooding is vital, there are the other pillars of SuDS to think about too: water quality, amenity and biodiversity. Previous articles in Drain Trader’s June 2023 and February 2024 issues, looked at water quality issues and what type of management trains were best suited to different types of development, depending on pollutant loads.

Operational and maintenance costs for SuDS schemes are often overlooked and ignored, but the promised implementation of Schedule 3 of the Flood and Water Management Act 2010 in England will shed a harsh light on these. SuDS Approval Bodies (SABs), likely to sit within local authorities, will require robust information about inspection and maintenance regimes and expected costs over the lifetime of a development.

An article in Drain Trader’s March 2023 edition looked at why poorly thought-out SuDS can lead to shorter service lives and higher operational costs than those expected from the design.

Mimicking nature

On a greenfield site, the first 5mm of rain would not typically generate surface runoff, it would infiltrate into the ground, evaporate or transpire through the leaves of plants.Then, when water flows from the surface of a catchment and exceeds the capacity of the receiving water body, the additional volume of water would spill over onto the floodplain.

When we develop on that catchment to add impermeable surfaces, such as roofs, roads and hard standings, the amount of surface water runoff generated can increase dramatically. In a dense, urban environment, 95% of the rainfall could flow off the catchment as surface runoff, increasing the volume of water that reaches watercourses or sewers. It is also likely that the peak flow will be higher and come sooner,than had it remained a greenfield site.

CIRIA C753 The SuDS Manual gives a graphical illustration of this. Figure 3.1, in Chapter 3 which deals with design for water quantity, shows hydrographs for the discharge rates of surface water for an area in three situations: when it is greenfield; when developed without flow attenuation; and when developed with flow attenuation.(Figure 1 shows a similar graph, courtesy of SUSDRAIN).

The amount of water that a SuDS system will need to attenuate or store, and the rate at which the water should be discharged is the subject of the hydraulic design for that system. For those that want to go back to first principles, these are set out in BS EN16933-2 Drain and sewer systems outside buildings–Design–Part 2: Hydraulic design.

Today, however, many drainage engineers rely on software such as Info Drainage and Micro Drainage (AutoDesk/Innovyze), Flow (Causeway) and Site3D. But this ‘blackbox’ approach to calculations can mean that designers don’t have the opportunity to properly understand the assumptions and coefficients that have been used–and the impact on water quality based on the SuDS components selected to satisfy the hydraulic design–which may lead to suboptimal performance.

In a SUSDRAIN factsheet from March 2014, Assessing attenuation storage volumes for SuDS–another useful resource for designers–author Anthony McCloy explains the risks of this approach:

“Don’t expect exact answers from the calculation process, it is a usable approximation that can provide acceptable solutions for design. Most of the inputs are based on statistics and calibration factors; therefore we can only ever achieve an approximation of how the system will behave in reality. The results of calculations and modelling need to be used alongside professional judgement to provide the design.”

Ten years later, this point is just as relevant as ever, perhaps even more so as design software is more widely used, with newer generations of engineers never called on to design from first principles. McCloy also advises that those assessing potential SuDS,such as SABs, must also have a basic understanding of first principles of storage volumes and hydraulic design so that they can carry out their statutory duties.

Water storage toolbox

There are many ways that we can create storage for excess surface water. Storage can be online, meaning that flow enters the element, passes through and out the other side or offline where flow enters and exits via the same point. A design could include both online and offline storage where, for example, flow above the 1-in-30-year return period is directed offline to accommodate the 1-in-100-year event.

Vegetative or surface-based solutions include ponds, detention basins which are dry until excess water needs to be accommodated and swales which can be used to accommodate volume, as well as to communicate flow between SuDS elements and for infiltration.

Ponds can be an attractive choice, potentially ticking boxes for all the four pillars of SuDS. From a water quantity perspective, they must have sufficient capacity to cope with rising water levels during higher rainfall events throughout their design lives. Any sediment entering the pond will settle out quickly, since the sediment particles soon reach terminal velocity allowing them to settle to the bottom of the pond.

As an asset owner or adopter, it is important to anticipate the amount of sediment that will settle out over time, because the accumulated sediment must be somehow removed at intervals to allow the pond to provide sufficient storage volume. One issue that is sometimes overlooked in the design of ponds is providing safe and cost-effective means of accessing the pond to remove sediment when required.

A recent story from Gloucestershire illustrates the costs involved. Local residents petitioned Gloucester City Council in January this year to desilt Saintbridge pond in Abbeydale because it produces a foul smell in the summer and the silt is negatively impacting on water quality and habitats. The council refused, saying that it was only 15 years since it last desilted the pond and that the operation would cost £700,000.

Commenting on the story, Jo Bradley, director of operations at Stormwater Shepherds,pointed out the error of not having installed an upstream sediment separator at the same time as the pond. “If a manufactured sediment separator had been included, it could have been emptied every year, costing maybe £700-£1000. That would have cost up to £20,000 over the 20-year cycle and avoided the £700,000 cost that they are now facing.

”Bradley pointed out that by bringing in heavy plant every 20 years, removing vegetation and sediment, the pond’s habitats and inhabitants are disturbed, negatively impacting on nature. And she added that the sediment in the pond could well be contaminated with toxic, bio-accumulative pollutants and tyre-wear particles. CIRIA’s manual says that a sediment separator or sediment forebay should be installed upstream of every pond. And, depending on the pollutants likely to be washed into the pond with the surface water, other pre-treatment could be needed. Without this, there is a danger that wildlife will be attracted to the pond, only to suffer harm from the pollutants within it.

This point was illustrated by researchers at Glasgow University, who compared SuDS ponds with natural ponds and found that pollutants were higher in some of the SuDS ones, negatively affecting amphibian breeding and development. A paper published on the research issues this warning:

“The function of SuDS and other urban drainage systems to sequester pollutants increases their potential to be ecological traps by advertising false cues of suitable habitat.

”In the next issue, Stuart considers what the options are available when considering proprietary attenuation solutions.

Reduce below-ground SuDS attenuation costs with ADS StormTech

Great News! ADS StormTech stands out as the sole SuDS attenuation and water quality management system with 3rd party verified Mitigation Indices (MIs), officially recognised for saving both time and money.

For detailed results, visit the British Water website.

ADS StormTech’s below-ground SuDS attenuation system uniquely meets water quality requirements for certain projects without the need for additional SuDS components in the treatment train. This translates to potential savings on both capital and maintenance costs.

The MIs for Isolator Row, the inbuilt water quality treatment device in ADS StormTech, are impressive: TSS = 0.8, Metals = 0.6, and Hydrocarbons = 0.7. These values comply with Medium pollution hazard applications per Table 26.2 of CIRIA C753 The SuDS Manual and also meet TSS requirements for High pollution hazard applications.

All results are 3rd party verified, calculated in line with The SuDS Manual and the British Water ‘How To Guide’.

To read to full article click here.

Improved solutions in stormwater management

The government’s plan for water, coupled with the implementation of Schedule 3 of the flood and Water Management Act 2010 in England, addresses concerns over wastewater discharges and the ageing sewer system in the UK.

These innovations pave the way for the inclusion of sustainable drainage systems (SuDS) as standard practice in the design, construction and adoption of new developments starting in 2024.

SuDS Treatment Train

Effective SuDS are designed to revolve around a treatment train that tackles both water quantity and quality. With various natural and engineered alternatives available, with optimum solutions balancing factors including cost, space availability, flow rates and pollutant loading.

TSS Removal

Stormwater runoff typically contains sediments, metals, hydrocarbons and nutrients. Total suspended solids (TSS), or particularly matter, are a primary factor for water treatment as they carry TSS removal is crucial for water quantity, preventing capacity reduction for storage and flow.

Isolator Row in ADS StormTech

ADS StormTech offers an underground SuDS attenuation system that offers integrated water quality management. The Isolator Row has two treatment stages, this provides gravity separation and filtrations through a geotextile fabric. Downstream StormTech chambers offer an additional treatment stage, where pollutants can absorb onto stones. This breaks down over time into non-polluting material. The Isolate Row has been tested and validated to remove over 80% of TSS, metals, hydrocarbons, phosphorus, nitrogen, and other pollutants. It’s easy to maintain using standard sewer cleaning equipment.

To find out more about Improved solutions in stormwater management read our full article here.

How SuDS can help meet new Water Management requirements

In April 2023, the Department for Environment, Food & Rural Affairs (Defra) published its Plan for Water. The aim of the plan is to create a more holistic approach to water management, ensuring that there is enough water to supply the UK’s growing population, and that the water in rivers, lakes and other water bodies is free from pollution. It promises action on all sources of pollution: wastewater treatment, agriculture, plastics, urban stormwater and road run-off, and chemicals.

Public awareness and concern about water quality, and how it impacts on the natural environment and on public health, is growing fast. And stormwater is increasingly being recognised as a big issue. As rainfall events become more intense, and our ageing sewer system becomes ever more overloaded, combined sewer overflows – where wastewater is discharged into rivers and other water bodies – are being activated more frequently.

New legislation will be welcome then – which is what the Government is suggesting in its Plan for Water. Among the proposed legislation are changes to planning policy so that new developments are designed to reduce the likelihood of both flooding and water shortages. Water companies, which will have to produce Drainage and Wastewater Management Plans, could be involved in planning decisions.

The Plan also references the Government’s plans to finally implement Schedule 3 of the Flood and Water Management Act 2010, which covers SuDS approval and adoption, in England – subject to consultation. Initially announced in January 2023, this could make the inclusion of SuDS standard practice in the design, construction and adoption of nearly all new developments from 2024. It also talks about the strategic road network and how it needs to do more to prevent pollution from highway run-off discharging into our water courses (see box).

Bioswale at a development in Hampshire taken in March 2023, showing how good SuDS can be.

Multi-faceted SuDS

Well-designed SuDS can help reduce pollution in a variety of ways. SuDS should be multi-faceted, dealing with water at source to prevent activation of combined sewer overflows (CSOs) and flooding and removing pollutants to improve water quality – as well as boosting biodiversity and providing public amenity.

Good SuDS design is based on the SuDS treatment train, or SuDS management train, which sees water passing through a logical sequence of stages using different SuDS components. The treatment train should consider both water quantity and quality, with the weighting given to each dependent on predicted water volumes, flows and the levels and types of pollution.

A SuDS train should start with prevention such as reducing impermeable surfaces, to reduce run-off and removing sources of pollution. Next comes source control, where rainfall is dealt with close to where it falls by infiltration-based elements such as soakaways, rain gardens and permeable pavements. Site control sees water managed within a local area, for instance directing water to a soakaway or infiltration device and then onto an attenuation pond or tank. Finally, regional control would see a system that could handle run-off from several sites, perhaps resulting in a detention basin or wetland.

The SuDS Manual, C753, published by CIRIA, prescribes a risk-based approach to designing SuDS for water quality. If pollution risks are deemed to be low, then SuDS designers can prioritise water quantity, amenity and biodiversity. If they are medium, then all considerations must be balanced. And if they are high, water quality evaluation must take precedence, for instance on haulage yards, industrial sites, trunk roads and motorways. It should however be noted that in all cases, including medium and low pollution risk sites, appropriate mitigation should be put in place to reduce the risk of pollution.

Heavy rain causing stormwater runoff from a road in Hoghton, near Preston, Lancashire in May 2022.

There are a range of water quality treatment measures that can be included in a SuDS train. Sometimes it is possible to use a completely natural SuDS train to deal with both water quantity and quality issues. At other times, the best solution combines natural and engineered SuDS elements, or may require proprietary manufactured elements only. This could be due to high levels of pollution loading or the space available.

There are four main types of pollutant that can be found in stormwater run-off: sediments, metals, hydrocarbons and nutrients. Sediments, often referred to in pollution mitigation as total suspended solids (TSS), is particulate matter. It includes tiny particles of soil, such as silt and clay, which have been dislodged by rainwater as it passes over the run-off surfaces.

Metals and metal compounds can be dissolved in run-off or attached to silts and sediments in the water. Copper and zinc are most commonly found in surface water in the UK but there can be cadmium and other toxic metals too. Although plants require very small amounts of copper and zinc to grow, higher concentrations can be damaging to them.

Hydrocarbon pollution comes with run- off from roads, car parks and areas where machines operate and are maintained, due to oil and fuel spills, tyre and brake wear. Changing climate means that rainfall events can be further apart but more intense, which can lead to higher concentrations of pollutants from roads, as they build up for longer before being washed away. Nutrient pollution, usually nitrogen or phosphorous based, can come from sources such as run-off from agricultural land where fertiliser has been used or CSOs, where waste water and surface water are discharged into bodies of water. They can lead to algal blooms, which reduces oxygen and can negatively impact on aquatic habitats. The Plan for Water reports £2.5bn of planned and made investment in wastewater treatment works between 2020 and 2025, which it says will halve phosphorous pollution. And it promises legislation to force water companies to make upgrades to nutrient removal near protected habitats. The Government’s Environment Act 2021 set a legally binding target to reduce phosphorus in treated wastewater by 80% by 2038 compared to a 2020 baseline, with an interim target of 50% by 2028.

Recent studies carried out by Stormwater Shepherds have indicated that phosphorus pollution is not a major problem from most urban surfaces. However, well designed SuDS can help alleviate nutrient pollution where it is a problem in surface water run-off. CIRIA guide C808, Using SuDS to reduce phosphorous in surface water run-off, published in 2022, provides guidance on how to do this. It suggests a treatment train starting by maximising infiltration, followed by sedimentation and the removal of solids and finally the introduction of actively growing plants to take up some of the dissolved phosphorus.

Wildflowers in a SuDS scheme in Chorley in Lancashire.

Capturing TSS pollution should generally be the focus of water treatment strategies in SuDS design since this removes both the solid particles and any pollution clinging to them. This can be done using a natural SuDS feature, such as planting for bioretention or a swale. Manufactured components such as filtration devices, silt traps or vortex separators can also be used upstream to remove solids before water is discharged into ponds, for instance.

Removal of sediment and solids is also important from a water quantity perspective. Build-ups reduce the capacity of a water storage element, whether natural or manufactured. How and when to remove sediment should be considered at the design stage and should be part of a planned maintenance regime.

Without a means of reducing suspended solids upstream of an attenuation device, sediment build-up within the device can reduce its efficiency over time. Some recently Introduced underground SuDS

attenuation devices have their own built-in systems for intercepting solids which are fast and simple to maintain.

SuDS in the Sheffield Grey-to-Green scheme, photographed in May 2022.

Mitigation Indices

The SuDS Manual sets out a simple method for dealing with water pollution risks, requiring the determination of pollution hazard indices for the area under consideration and then matching a SuDS device with matching mitigation Indices.

In Table 26.2, the manual provides pollution hazard indices for a range of land uses and for three types of pollution: TSS, metals and hydrocarbons. So, for example, for a busy public car park such as a supermarket or hospital, the index for TSS is 0.7, for metals is 0.6 and for hydrocarbons 0.7.

The next step is to identify a form of SuDS treatment that can provide the necessary mitigation indices, either as a single treatment stage or using a combination of components. The manual has a table for that too, Table 26.3. However, this table only provides indices for natural SuDS components, stating that proprietary treatment systems must demonstrate that they can address each of the contaminant types to acceptable levels.

The mitigation indices for the natural SuDS components were compiled by a team of experts, drawing information from a selection of published papers. More recently, in 2016, British Water published a Code of Practice for the Assessment of Manufactured Treatment Devices Designed to Treat Surface Run- off. It combines the rainfall time-series data for the UK to determine an appropriate treatment flow rate based on first-flush principles and uses a combination of two test protocols – the German Deutsches Institut für Bautechnik (DIBt) and the New Jersey Comprehensive Assessment Tool (NJCAT) from the US – to create the British Water test methods.

In 2022 British Water has also published a How To Guide, Applying The CIRIA SuDS Manual (C753) Simple Index Approach To Proprietary/Manufactured Stormwater Treatment Devices, which provides a calculation methodology to derive mitigation indices for TSS, metals and hydrocarbons based on the Code of Practice, or the DIBt or the NJCAT, test results. This allows manufactured treatment products to have their mitigation indices published so that they can be considered as part of a SuDS Management Train, often alongside vegetative treatment components.

The value of water quality

One of the challenges in the delivery of well-designed SuDS treatment trains is that important elements of the train can be removed during ‘value engineering’ exercises. For instance, a design or specification may include guidance to say that sediment should be removed upstream, but this is then considered unnecessary during a ‘value engineering’ exercise and removed or compromised.

Unfortunately, decisions like this are about short-term capital cost rather than whole life cost. They don’t consider the important issues of how maintenance should be carried out, its frequency and its cost – in terms of both cash and carbon. It may also result in failure of the system to continuously provide the required performance according to the original design, throughout the life of the development. Should Schedule 3 of the Flood and Water Management Act come into legislation, maintenance and longevity issues will be brought to the fore. In Wales, where Schedule 3 has already been adopted, developers are expected to create a maintenance plan and the adopting authority will be required to carry out the maintenance for the design life of a scheme.

SABS within county and unitary authorities will be responsible for securing the means to maintain the SuDS they adopt, and it could be that the regulatory framework in England is similar to that used in Wales. As currently understood, funding will be provided by the developer in the form of a commuted sum to the SuDS Approval Body (SAB) at the point of handover. The timeframe for the enactment of Schedule 3, and the many other pieces of proposed legislation for the Plan for Water, remains uncertain – not least due to the uncertainty over when the next general election will be held. However, the urgent need to address water quality issues will only move up the political agenda.

Incorporating SuDS trains that manage both water quality and quantity into new developments does not necessarily have to increase capital costs. Good design can reduce costs over the lifetime of the SuDS and the development.

Highway run-off

Pollution due to road run-off is a major problem in the UK. There are estimated to be over one million drains and outfalls from the strategic road network and local authority roads, the majority of which run straight into rivers and other water courses with no measures to treat the pollution in the water before they do.

The result of this is a build-up of toxic pollution in riverbeds, water, fish and other aquatic life. Run-off from roads contains high amounts of suspended solids which sit on the bed of a watercourse, bringing with them other pollutants which are released over time. Pollutants include polycyclic aromatic hydrocarbons (PAH), metals and microplastics from brakes and tyres.

Only 4,000 out of 26,000 outfalls and soakaways from the Strategic Road Network, run by National Highways in England, have measures in place to treat pollution. The Environmental Permitting Regulations say that highways authorities can discharge road-run off into water bodies only if it doesn’t cause pollution. However, the Environment Agency has never required a road authority to apply for a permit where polluted road run-off is discharging straight into rivers and other water bodies.

The Plan for Water does mention this issue, but there is no firm plan for action when it comes to road run-off. Instead, it says that it is “considering actions to take to reduce the impacts of the Strategic Road Network on water quality as part of developing the next Road Investment Strategy.” The Government will also consider ‘targeted action’ for roads owned by local authorities whose road run-off is contributing to pollution. This falls short of the urgent action which the House of Commons Environmental Audit Committee (EAC) called for in its Water Quality in Rivers report, published in January 2022. One of its suggestions was that the Environment Agency should require discharge permits for any road with annual average daily traffic above 15,000 vehicles.

National Highways has a target of improving 17.5km of water bodies every year.

The plan reports that to date National Highways has delivered over 30 water quality initiatives which have improved just under 20 miles (32km) of water bodies. In 2020-21, its annual report said it had improved 17km of waterbody, so it appears to be missing its targets. There are a number of ways that run-off from roads can be treated for pollution before it enters a water body. SuDS can be used as part of the water treatment train.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 50,000 below ground SuDS attenuation system installations using in excess of 3m units.

Originally published in Drain Trader magazine June 2023

For more information on Advanced Drainage Systems, visit www.adspipe.co.uk.