Author Archives: Nathaniel

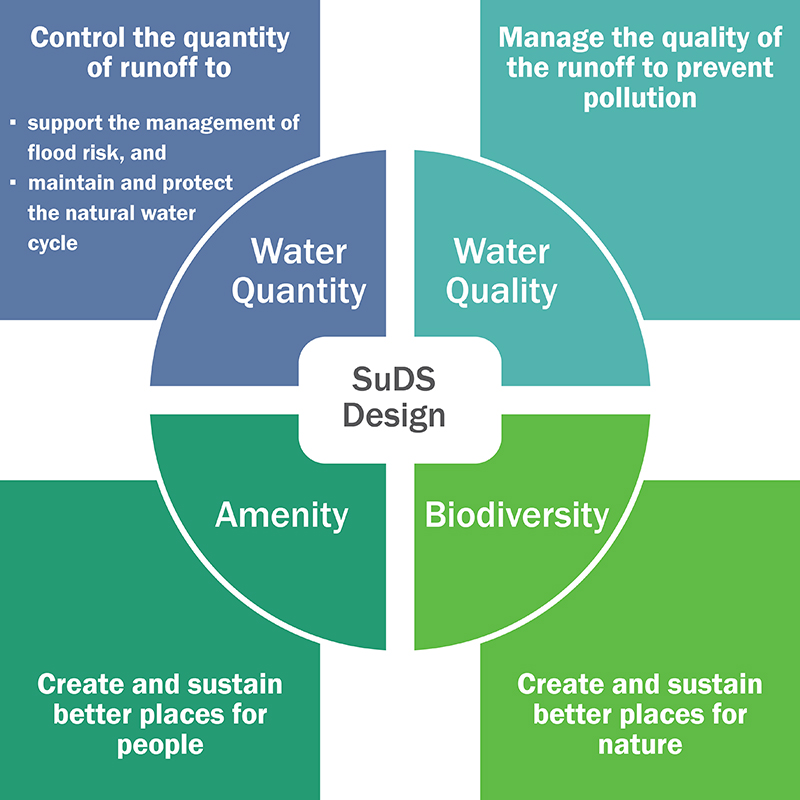

New rules for SuDs and pollution management

The Departments for Environment, Food and Rural Affairs (Defra) launched The Plan for Water in April. Designed to “transform management of the water system, clean up the water environment and create a sustainable supply of water for people, business and nature”.

However, The Plan for Water is not the only recent initiative that revealed a sharper focus on the environment and water management. Earlier this year the Government announced its intention to implement Schedule 3 of the Flood and Water Management Act 2010 (FWMA) in England. This will accelerate the adoption of SuDS and enforce statutory requirements for the planning, design, construction and maintenance of assets.

With SuDS and water quality at the heart of the new government initiatives, designers will be relieved to learn that with ADS StormTech , there is a storm water attenuation system that has water quality as an integral part of its design. To book a CPD seminar, simply click here or call 0203 442 0607. To find out more about The Plan for Water read our latest newsletter here.

StormTech tanks leading the charge to greener cities

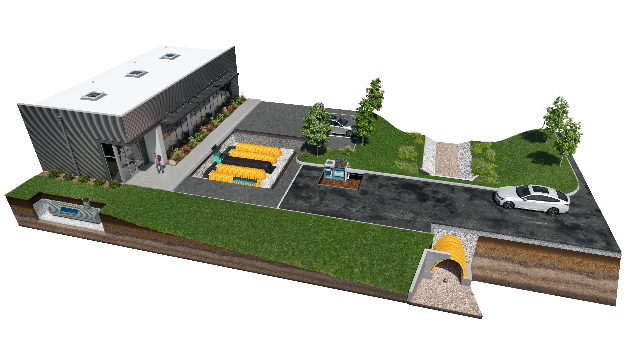

StormTech chambers can be an integral part of a green infrastructure project by offering additional scope for the designer to enhance performance and resolve technical issues.

StormTech has previously been used in a variety of GI applications including, pavements that allow the movement of water through the surfacing

material. The StormTech system can be installed below the pavement or used in combination with other SuDS systems to enhance the water storage capacity and pollutant removal performance.

In Francisco Park 372 StormTech chambers were installed in the existing reservoir to provide a total storage capacity of 2,000m3 of water. This has enabled the reservoir to be transformed into a sustainable and cost-effective community space with a stormwater capture and reuse system that will perpetually provide water for the park’s irrigation and toilets.

StormTech was chosen for this project as they provided the best ratio of storage volume to footprint area.

StormTech is manufactured by Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of corrugated thermoplastic drainage pipes and a specialist in water management systems. To read the full story click here.

ADS meets Eurocode design loading

ADS StormTech below ground SuDS attenuation has been used within over 50,000 projects worldwide. Eurocode modelling demonstrates that the standard StormTech Construction Guidelines for minimum and maximum cover depths can be used for both shallow and deep applications.

This enables the SuDS attenuation system to be installed under roads with HGV traffic loading with a cover depth as shallow as 350mm. StormTech’s arch-shaped chambers are designed and manufactured to codes and standards published by the American Association of State Highway & Transportation Officials (AASHTO) and the ASTM international.

Thanks to the wide range of StormTech chamber sizes available design can be adapted to meet many site configurations. All sizes of the StormTech chamber have been analysed using a finite element analysis (FEA) model to Eurocode design principles. In the most demanding loading scenarios and the calculations proved that all StormTech chambers are structurally adequate for each of the four Eurocode load model cases.

StormTech is now available in the UK and other European countries. With no “equivalent” standard to the AASHTO or ASTM available in the UK, ADS commissioned a modelling study to demonstrate their performance under the Eurocode design methodology.

To read the full story read our eNewsletter.

SuDS tips #5: Design Flexibility

A qualified civil engineer, Stuart Crisp has been at the forefront of construction and a specialist in drainage systems for over 35 years. He has contributed to the development of numerous British and International Standards and industry specifications and was a member of the project steering group for CIRIA C753 The SuDS Manual. In this regular series of articles, Stuart considers the different challenges facing designers and installers of below ground SuDS attenuation systems. This month covers the importance of design flexibility.

When designing a below ground stormwater attenuation system, it’s important to consider not only the hydraulic and structural requirements, but the site conditions, the construction process, the necessity for maintenance, the environmental concerns and the technical, legal and client constraints.

The flexibility of the system to accommodate a multiplicity of factors is thus central to the solution – can the design be optimised to meet the relevant conditions and controls? A truly adaptable stormwater attenuation system will mean engineers can produce the most effective design, contractors can install the system with speed and ease, and asset owners can inspect and maintain the system efficiently, whatever the conditions.

Traditional pipe- and crate- based solutions have their drawbacks. Large diameter pipes are less efficient in terms of the ratio of footprint area to attenuated storage volume. Geocellular crates may have greater versatility to meet challenges in terms of accommodating storage within the space available, but the necessity for additional TSS removal and separate water quality treatment to meet environmental quality standards can add to the cost of construction and upkeep.

With the importance of design flexibility, ADS StormTech comes in a wide range of chamber sizes giving engineers the scope and flexibility to meet required attenuation volume and flow rates, the constraints of the site, the installation footprint and depth, and the position of inlets and outlets. Isolator Row, the free water quality treatment device, provides a provenly effective and low maintenance solution for meeting environmental standards. Layouts can be adapted to suit local conditions, potentially going beyond the published standard construction guidelines. For example, deep installations or poor soil strength may be accommodated by altering the spacing between the chambers, the depth of the foundation material and the degree of compaction of the embedment stone.

This is particularly true when minimising the construction depth of the attenuation system. This largely depends on two factors: minimum cover depth and the height of the stormwater storage system. Shallow systems may help avoid contact with high groundwater, and lower dig depth can reduce dewatering costs and installation delays in saturated ground. Shallow systems can also minimise the cost of excavation, muck-away and embedment/backfill, including fewer transport movements to and from the site. Reducing the depth of the attenuation system may also enable the invert depth of the entire storm water drainage system to be raised, resulting in additional cost savings extending beyond the attenuation system itself.

Many StormTech chambers have 450mm min cover depth under HGV traffic loads based on the standard manufacturer’s installation guidelines. Pipes and crates normally need c600mm – 800mm min cover depth. For crates, if the depth of cover available is less than the minimum recommended by the manufacturer, a protective concrete slab is frequently placed above the crate system. This is expensive and time-consuming to construct and makes it almost impossible to access the system from above after installation.

Quality Assurance is inevitably a key part of true design flexibility. StormTech fully complies with the requirements of ASTM F2787, ASTM2418 and ASTM F2922 and Section 12.12 of the AASHTO LRFD Bridge Design Specifications safety factors for live and permanent earth loads. These Standards provide the basis of product quality and of safe structural design. Further assurance is provided in the UK through rigorous independent testing and assessment within the scope of BBA certification.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine July 2022

SuDS tips #4: Water Quality Management Solutions

A qualified civil engineer, Stuart Crisp has been at the forefront of construction and a specialist in drainage systems for over 35 years. He has contributed to the development of numerous British and International Standards and industry specifications and was a member of the project steering group for CIRIA C753 The SuDS Manual. In this regular series of articles, Stuart considers the different challenges facing designers and installers of below ground SuDS attenuation systems. This month covers water quality management.

Water Quality Management – mitigating the impact of pollutants in surface water runoff to prevent harmful discharges into the environment – is one of the fundamental principles of SuDS Best Practice. Essentially, this covers three key material groups:

- suspended solids – silt and other particulate material flushed off the drainage catchment surface

- hydrocarbons – oil and petroleum-based materials deposited (or spilt) on the ground, usually as a result of vehicles and machinery in operation, or worked on, in the vicinity.

- Metals – a range of metals-based materials that can cause harm to the environment, including copper, zinc, lead.

Increasingly, Water Quality Management is a key focus for SuDS systems. Planners are looking to provide “nutrient neutrality” i.e., reducing existing sources of nutrient pollution to mitigate the nutrients generated by new development. In these more demanding cases, removal of additional substances such as compounds of phosphorous and nitrogen are often required.

It is the job of key stakeholders in the Project Team to ensure that the water quality discharge meets the requirements of legislation, client, and the local environmental regulator.

Numerous reference sources exist that can help users determine the most appropriate water quality mitigation measures for a specific project. These include the CIRIA publication C753 The SuDS Manual. Chapter 4 deals with Designing for Water Quality and Chapter 26 deals with Water Quality Management. Chapter 14 relates to Proprietary Treatment Systems. Other Chapters provide guidance on specific vegetative “soft” SuDS components such as Detention basins, Swales, Infiltration systems and Filter strips. Vegetative SuDS are generally regarded as preferable in terms of SuDS Best Practice, as they are surface based solutions that manage rainfall closest to where it lands, also referred to as “source management”. Like any system, vegetative SuDS will require maintenance to ensure that they meet their design function throughout the lifetime of a development.

Designing an effective below ground SuDS attenuation system that meets the demands of both flood risk mitigation (Water Quantity Management) and pollution risk mitigation (Water Quality Management) requires a Management Train approach, where proprietary Water Quality Treatment device(s) are usually installed upstream of the below ground Attenuation Tank. This would typically require a sediment capture system, which may be as basic (and potentially inadequate?) as a catch pit or more appropriately, a proprietary gravity separation sediment tank or hydrodynamic separator. Hydrocarbon removal will require a bypass or full-retention oil/water separator, depending on the intended use of the development and the level of risk of hydrocarbon pollution.

Below ground attenuation systems such as crates and pipes offer little in the way of water quality treatment capability, so the demands of water quality must be covered by separate, additional SuDS components elsewhere in the system.

Not only can this require significant capital investment in the treatment system (each manufactured treatment device can cost >£10k, and multiple units may be required on a project), there is an additional operational cost in terms of inspection and maintenance. Failure to properly maintain water quality treatment systems can lead to problems with the attenuation tank, such as sedimentation within the tank, resulting in reduced storage volume– causing the system to fail hydraulically – and the possibility that pollutants are flushed downstream, resulting in water quality breaches and fines.

Some systems, however, include an integrated solution. New to the UK, the ADS StormTech stormwater attenuation system incorporates the unique Isolator Row, a patented, built-in water quality treatment device designed to remove silt and other polluting material flushed off the surface during rainfall.

Isolator Row has 2 treatment stages, contributing to the overall efficiency of the system. These include initial gravity separation of the silt and particulates within the Isolator Row chamber and filtration through a layer of woven geotextile fabric on the bed of the chamber, laid over a stone foundation. Two further treatment stages can take place within the stone embedment surrounding the StormTech chambers. As flow passes through the system, pollutants can adsorb onto the face of the stone, meaning that they are “trapped” and prevented from passing through to the discharge point. This material can provide nutrient for bacteria and over time, will be broken down into harmless, non-polluting material.

The four treatment stages of a StormTech system:

- Gravity separation (sedimentation) Isolator Row (2 stages)

- Filtration

- Adsorption Embedment stone surrounding StormTech system

- Biodegredation

Isolator Row has been independently tested by universities and respected industry bodies (including NJCAT) and validated to remove over 80% of Total Suspended Solids (TSS) plus metals, hydrocarbons, phosphorus, nitrogen, and other surface water pollutants.

Where nutrient neutrality is sought and there is a demand for higher levels of pollutant removal, or where more challenging pollutants need to be dealt with, other water treatment solutions may be required. These can include proprietary filtration systems designed specifically to address certain chemical species and material phases within the surface water runoff. In these situations, when considering a proprietary manufactured treatment device, it is recommended that advice is sought directly from the manufacturer.

For practitioners in the UK, it may be helpful to refer to the British Water Code of Practice: Assessment Of Manufactured Treatment Devices Designed To Treat Surface Water Runoff. This publication sets out an assessment method to measure pollutant capture and retention. Additionally, read in conjunction with the Code of Practice and the CIRIA SuDS Manual, it is possible to derive mitigation indices using the British Water How To Guide: Applying The CIRIA SuDS Manual (C753) Simple Index Approach To Proprietary/Manufactured Stormwater Treatment Devices.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine June 2022

SuDS tips #3: Designing low-maintenance solutions

A qualified civil engineer, Stuart Crisp has been at the forefront of construction and a specialist in drainage systems for over 35 years. He has contributed to the development of numerous British and International Standards and industry specifications and was a member of the project steering group for CIRIA C753 The SuDS Manual. In this regular series of articles, Stuart considers the different challenges facing designers and installers of below ground SuDS attenuation systems. This month covers the subject of inspection and maintenance.

When designing a stormwater attenuation system, sometimes too little attention is paid to cleaning and the costs of ongoing maintenance. System maintenance is essential to ensure that the intended performance is retained throughout the service life and that the risks of flooding and pollution are avoided.

This vital part of asset management can be overlooked at both the design and procurement stages, as the choice is often based on the incorrect assumption that all below-ground attenuation systems are equally easy and low-cost to maintain.

However, this is not the case. For example, because of their structure, stormwater attenuation crates are difficult to get access into the body of the tank for cleaning and require upstream silt removal to prevent a downstream build-up of material within the tank body. Whilst large diameter pipes are easier than crates to access, they too require upstream intervention for silt and hydrocarbon removal.

Both pipes and crates are therefore dependent on the additional expenditure and maintenance of an upstream silt separation and removal system. If silt gets into the storage tank, it can compromise the flow path and reduce the storage volumes – eventually causing the whole system to fail.

But that’s not all. Silt particles can carry pollutants and if these get into the storage tank, they may flush downstream and result in water quality breaches, pollution, and fines.

Crates and pipes, therefore, depend heavily on expensive upstream pre-treatment systems which, together with the attenuation tank, require regular inspection and maintenance. Conversely, the ADS StormTech stormwater attenuation system may not require additional upstream pre-treatment, therefore reducing capital and operational costs.

This is because ADS StormTech is engineered to provide an efficient, durable, low-maintenance solution for commercial, residential, industrial, and infrastructure installations. A key part of this is the unique Isolator Row, a ‘free’ built-in water quality treatment device designed to remove silt, sediment, and polluting material flushed off the surface during rainfall. Isolator Row is “sacrificial”, meaning that other StormTech chambers within the system are protected from solid particles and pollutants in the runoff entering, and they will not require any cleaning during their service life. This keeps maintenance to a minimum. Furthermore, Isolator Row has been independently tested by universities and respected industry bodies, including NJCAT, and validated to remove over 80% of Total Suspended Solids (TSS) plus metals, hydrocarbons, phosphorus, nitrogen, and other surface water pollutants. Isolator Row, as an integral part of the StormTech system, is recognised by many authorities as a water quality treatment device.

After many years of successful use in over 40,000 installations worldwide, Isolator Row has been proven to need cleaning on average once every 3-7 years, depending on the nature of the installation, using standard sewer cleaning equipment, saving asset owners both time and money in stormwater system maintenance.

Stuart Crisp is UK Manager for Advanced Drainage Systems (ADS). ADS is America’s largest manufacturer of thermoplastic corrugated drainage pipes and a specialist in water management systems. StormTech has a long and successful track record with over 40,000 below-ground SuDS attenuation system installations using in excess of 2.5m units.

Originally published in Water magazine, May 2022